If you are a designer and engineer, and need to source the parts that created through , CNC machining, milling, and turning, grinding, fabrication. A machine shop is essential. When ordering parts for CNC machining, you will need a machine shop with compatible services for the project requirements and product specification. Especially to match the capability of tolerance control and overall precision. For this reason, we will tell you why you can find and choose the best precision machining services is so important.

How to select the best precision machining services?

1. Know the background and its experience of manufacturing

The first important step in selecting the best manufacturer for precision machining services is to understand what they have done in the past, what kinds of industries they served or even who are their typical customers, must be with good experience and good feedback from clients. Also You will have to look for someone how long has been in the business and service.

Manufacturers who are with an in-depth experience in manufacturing are built over the years. They will be knowledgeable about the production processes and have a good reputation for product fulfillment and customer service.

2. Review capacity and capability of equipment

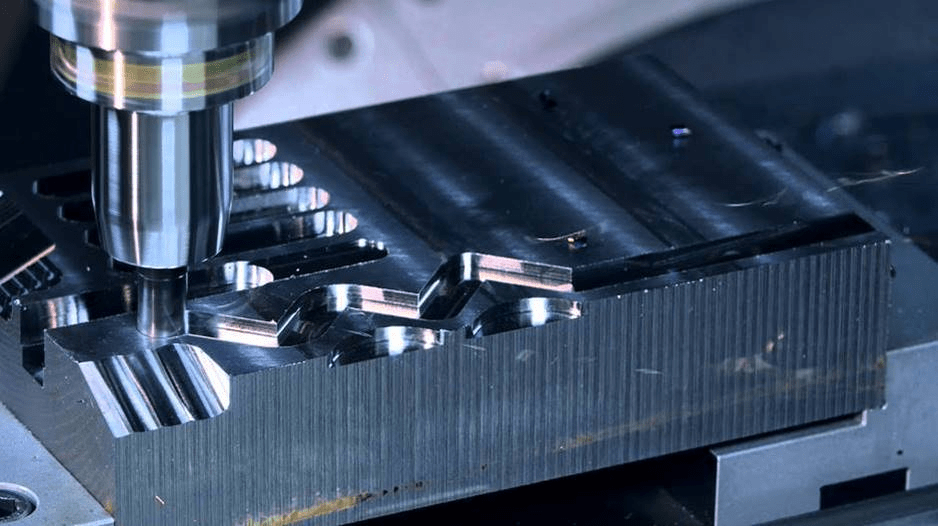

The other thing that you must look out for what equipment they have, ask for a machines list while selecting a precision machining service, or what systems and technologies they provide. For example, if the part needs five-axis CNC machining, what machines serve and what capacity they have, what exact parts they made in the past. Also there will not be a point in starting any discussion with a service that only comes with three-axis machines. Should be dedicated in discussing of process base on your needs. Make sure they have experience of making your needs.

If you have a flexible schedule, you should set up a factory tour and find out what exactly they can offer in either current case or future needs. Then you will have clear definition of what grade of service this manufacturer can do.

3. Find out quality assurance operation

The quality team will begin by reviewing the project and quality requirements while working directly for your needs. You can check if the shop has diverse materials like stainless steel and titanium or the more common and soft aluminum 6061. It’s important for them to know the goal of project and how it will be judged based on its functional and non-functional qualities. This will indicate that the shop has the varied manufacturing experience to handle your future and present requests.

A experienced manufacturer must have their common standard of quality control besides your needs. Means the SOP(standard operational procedure) according the ISO9001. then they will have a clear frame to follow basically. To make sure your special needs to be remarked and strictly taken over.

4. Surface finishes and operations

Surface finishing is one finishing manufacturing operation applied to certain types of workpieces. This process alters the surface appearance of a workpiece by performing different actions that can reshape, remove, or add to the final product.

A manufactured part may need finishes like chemical conversion coating, nickel plating, electroplating, or even anodizing. It may also require features like laser marking, silkscreen, and installed inserts before shipment. Selecting a precision machining service that can perform secondary operations and finishes will give you an all-set component.

5. Operational risk

A good precision machining vendor supposed to have high sense of risk management, and its solution implemented upfront, either in DFM stage, or in process control. This will need an individual and a team to work on the parts and rectify any problems that may arise. Precision machining services only rely on a single person for doing everything from machining to quoting and quality assurance, which can indicate an operational risk. If anything happens to the person, your job can be sidelined. So internal clear operation procedure must be built and addressed.

You must avoid such risks by checking the activities and distribution of the vendor across the personnel range.

6. High Responsiveness

Responsiveness is one of the signals that the vendor to offer, the one that you select should be easily accessible and can proceed clear communication in language and technical. You can evaluate the potential vendors by paying close attention to the responsiveness, especially in the early stages of the engagement.

What kinds of skills that the manufacturer can offer for communication, While calling them, does anyone pick up, or do you just hear the voicemail? Or can have video calling ? Do you get an email response or a prompt return call after leaving a message? Can they proceed technical communication for discussing all details and problems directly ? The communication skills of a shop are significant for a long-term relationship with the vendor.

7. Checking for certifications

To determine the establishment of a precision machining service, you must check for its certifications. For example, if you need to manufacture aerospace application parts, you must go to a machine shop of the highest quality. Others like ISO9001:2015 & IATF16949:2016 & ISO13485:2016 FDA Certified.

You must also ensure that the production facility has the necessary certifications.

for instance, The production partner must have medical-grade facilities and necessary certifications if they order medical components and devices.

8. Evaluating lead times

Lead times is another factor that will help you choose the best precision machining services. Most quality machine shops list their usual turnaround times. However, these vary depending on the manufacturing job’s scale and complexity.

You need to know whether manufacturing partners can deliver and machine a part within the required time frame. Ask for their delivery history and satisfaction records that customer responds. This would be straight to the quality of their manufacturing service.

Conclusion

To make sure your needs taken over and handled safely, this is why to find the best precision machining service provider, the ones have experience, certifications, and safe lead times along with their fast responsiveness. JC Rapid provides precision machining services with cutting-edge technologies with a team of experienced and expert engineers and masters.

Questions? Contact our friendly sales team at engineers@jcrapid.com