Medical Industry

Get to market faster and streamline your supply chain with rapid prototyping and on-demand production of medical components

Manufacturing Solutions for Medical Devices

At jcrapid, we provide custom rapid prototyping and volume production services that are able to meet the unique needs of the medical industry. We pride ourselves on delivering fast response times, strict material verification and rigorous quality control at every stage of the manufacturing process.

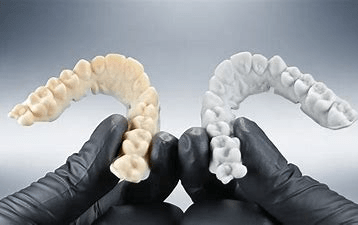

The medical industry relies on customized product solutions made to the highest standards. With a range of service offered in-house including CNC machining, polyurethane vacuum casting and a host of finishing services we can offer the customization and flexibility you need when building prototypes and parts quickly and accurately.

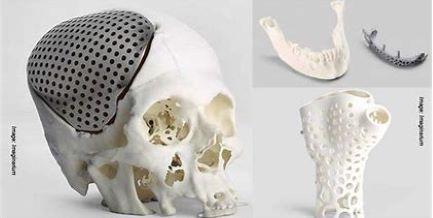

Applications we’ve made include fitness trackers, health monitors, drug delivery devices, enclosures and cases for medical devices, prosthetics and a range of other medical equipment. Another benefit is that we have no minimum order requirements and are adept at ramping up volumes from single prototypes to new product introduction and beyond.

Get to market faster by contacting us to see how we can help you manufacture your medical components.

Medical Device Prototyping

we offer reliable rapid prototyping and rapid manufacturing solutions crafted to suit the needs of the medical device industry. Regardless of our project load, our customers can rest assured that we will deliver high quality, precision products on time and at affordable rates.

Jcrapid Medical Device Prototyping Applications

- Handheld devices

- Medical carts

- Medical diagnosis equipment

- Medical monitor instruments

- Medical treatment devices

- Anatomical models

- Tables and panels

- Teaching aids

- Ultrasonic equipment

- Physiotherapy apparatuses

- MRI devices

- X-Ray equipment

- Clinical analytical instruments

- Care equipment

- Surgical instruments

- Electronic apparatuses

Common Medical Devices and Components We Produce

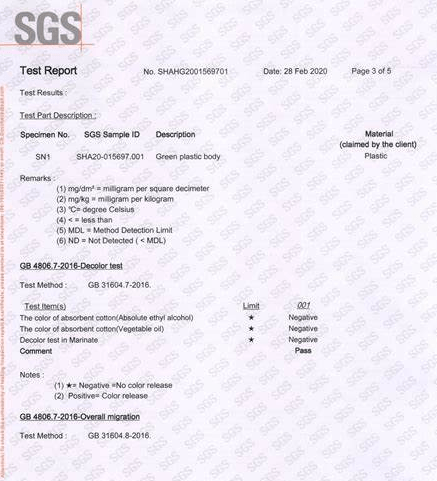

Quality You Can Trust With Inspection & Material Verification

Ensuring the reliability of the supply chain is critical in the medical industry. That’s why we use advanced metrology equipment to verify all incoming raw materials and will provide you with chemical analysis and full certificates of compliance for your peace of mind. To support the needs of the medical industry, we offer a range of materials including titanium, stainless steel, TPE, POM, PEEK, ABS, nylon, silicone rubber and more.

Our facility is fully certified to ISO 13485:2016, 9001:2015, 14001:2015 and 45001:2018 standards.

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries.

Agriculture Industry

Consumer Products

Electronics Industry

Automotive Prototyping

Common Medical Manufacturing Services

Rapid Prototyping

Vacuum Casting