vacuum casting

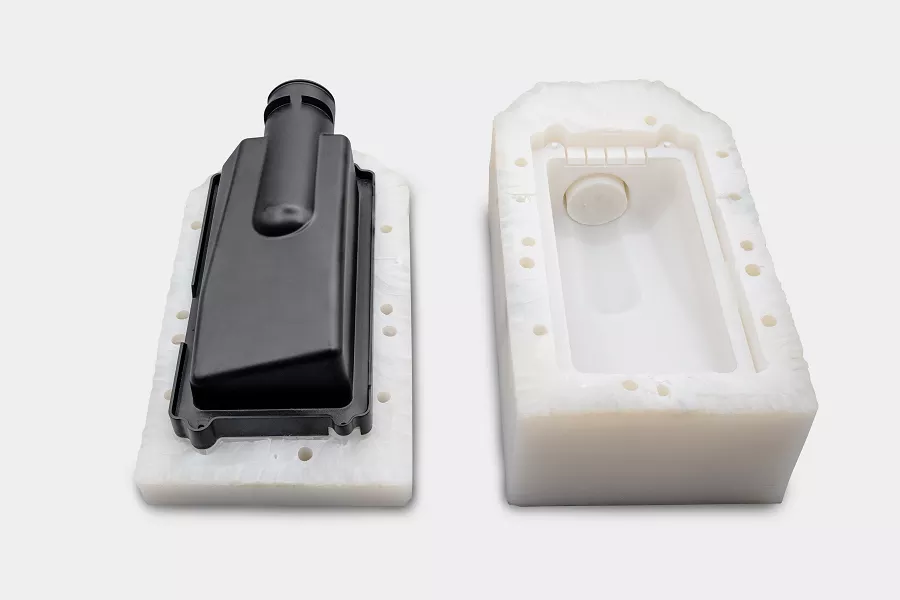

Use vacuum casting to produce end-use quality plastic and rubber parts. Vacuum casting is the perfect alternative when you need to optimize production cycle and balance cost, quality, and efficiency. Simply upload your STL files to get an instant quotation, manufacturability review, and get your parts into production seamlessly.

Vacuum Casting and Urethane Casting by JCRAPID

Vacuum casting or cast urethanes is a perfect solution for production quality parts without the cost or lead time required for production tooling. At JCRAPID we can cast parts as large and small, everything from headphones all the way up to 2m long car bumpers. We have a massive range of materials available for your projects.

What do we do ?

JCRAPID Vacuum Casting Service

JCRAPID provides online vacuum casting services (also known as urethane casting services, urethane vacuum casting services, or urethane casting services) manufacturing. With our professional manufacturing factory, JCRAPID provides turnkey solutions according to your CAD design and specific requirements (such as coloring and full line finishing, such as sandblasting, soft touch, screen printing, overmolding, etc.) to reach your expected aesthetic.

After receiving your 3D files, we will provide you with a quotation and lead time for the vacuum casting process and take care of the rest, including quality control. We will be solely responsible for the manufacture and delivery of the final product and, at any time, Inform you of every step of the casting process, master model creation, silicone molding, duplication, and finishing. All our production is ISO 9001 certified, and we use high-quality raw materials.

Vacuum Casting Materials

| Meterial | Color | Tolerance | Properties | Post Processing | Max. Printing Size (mm) |

|---|---|---|---|---|---|

| TPU | White | 250 μm or 0.25% | Hardness: softest-30°, standard-70°, hardest-90° Lead Time: 7days + 3pieces/day Max. Quantity: 100 Pieces Per Type Note: May have gate mark/oil residual on the surface | / | 900*700*600mm |

| TPU | Black | 250 μm or 0.25% | Hardness: softest-30°, standard-70°, hardest-90° Lead Time: 7days + 3pieces/day Max. Quantity: 100 Pieces Per Type Note: May have gate mark/oil residual on the surface | / | 900*700*600mm |

| TPU | Transparent | 250 μm or 0.25% | Hardness: softest-30°, standard-70°, hardest-90° Lead Time: 7days + 3pieces/day Max. Quantity: 100 Pieces Per Type Note: May have gate mark/oil residual on the surface | / | 900*700*600mm |

| TPU | Multicolour | 250 μm or 0.25% | Hardness: softest-30°, standard-70°, hardest-90° Lead Time: 7days + 3pieces/day Max. Quantity: 100 Pieces Per Type Note: May have gate mark/oil residual on the surface | Painting | 900*700*600mm |

Technical Specifications

Standard tolerances for Vacuum Casting

| Part size / dimension | Tolerance | Angularity |

|---|---|---|

| < 12’’ (300 mm) | ± .005’’ (0.125 mm) | ± 0.5° |

| < 24’’ (600 mm) | ± .010’’ (0.250 mm) | ± 1.0° |

| < 36’’ (900 mm) | ± 1/16’’ (0.400 mm) | ± 1.0° |

· High quality surface finish.

· Gate mark/oil residual may exist.

· Shrinkage may occur and the accuracy of silicone mold will be affected by the structure and size of the master model.

* For expedited lead times or parts that exceed the maximum build size contact [email protected].

Size limitations for Vacuum Casting

Requirement

Specifications

Maximum part dimensions

1900 x 900 x 750 mm

Minimum wall thickness

0.75 mm (recommended wall thickness 1.5 mm)

Duplication quantities

25-30 copies (depend complexity of the mold and casting materials)

Enquire About Vacuum Casting

Do not hesitate to contact us for more information about vacuum casting. Your customer support partner

will contact you directly to answer any questions you may have.

Custom Parts Prototyping Services

Rapid prototyping with vacuum casting

Rapid prototyping is manufacturing physical parts, models, or components using 3D computer-aided design (CAD). Creating a part, model, or component is typically done using additive manufacturing or 3D printing. They can also be manufactured using CNC machining and injection molding.

Rapid prototyping plastic parts manufactured with vacuum castingare characterized by a very high-quality prototype with a great wall thickness. They can be manufactured using low-volume silicone molding within very short production times.

- Pre-series prototype as a market test

- Precise prototyping

- Fully Functional models

- Design models and exhibition models

- Small series for the first marketing

- Precise surface finishing like overmolding

Vacuum Casting Advantage

1.Speed & Low Volumes Manufacturing

Vacuum casting is a simple and quick process to produce small batch items with high-quality prototypes; each silicone mold can duplicate 25x times.

2.Complex Shape & High Quality of Details

The urethane casting process is a good choice for parts with complex shapes; the silicone molding gives an optimal result on sharp corners and thin walls.

3.Versatility - Functional & Esthetic Parts

Vacuum casting allows the reproduction of any parts. The material with a large range of properties, finishing, and parts sizes help you to achieve any functional and esthetic parts.

4.Cost-Effective

Vacuum Casting is mainly used for low volumes of production. Each mold can duplicate 20 to 40 parts, and vacuum casting cost is very friendly and a great alternative to plastic injection molding.

Tooling Cost & Overturns

Small cost compared to injection machine

- Small tooling cost

- Quick manufacturing

- Master Model

- Duplicate parts easily

- 20-200 Batch production

- Manufacture any product ideas

Manufacturing Any Parts

Any parts can be done with Vacuum Casting

- Large parts

- Complex Shape

- Strong parts

- Lightweight parts

- Functional parts

- up 10 Cast materials

High-Quality

Result with vacuum casting is similar as injection molding

- Very high-quality parts

- Multiple finishing & post processing

- No Air bubbles

- 3d printing Alternative

- injection molding Alternative

- Extensive Wall thickness

Our Vacuum Casting Service for Various Industrial Applications

Due to its fast production, low costs, and durable parts, our vacuum casting service is the favored option for making custom parts used in the automotive, medical, consumer goods, and other industries.

Request a Free Vacuum Casting Quote Now

Contact JCRAPID today to get a free quote for your vacuum needs within 24 hours. Our professional team can speak to you in multiple languages and will answer any questions you may have.