Rapid Prototyping Services

JCRAPID offers a wide range of Rapid Manufacturing services that support our customers through each stage of the product introduction cycle: research and development, rapid prototyping, pre-production, testing, and market introduction

Rapid prototyping machining services you can reckon

Searching for the most cost-efficient and quality-providing prototype makers?

Look no further as you will get the most appreciated and customers’ favorite rapid prototyping machining at the most modest price around!

Let us help you prototype your dream product.

Contact today to get in touch with our experts! Ultimate satisfaction guaranteed!

21+ Years

Manufacturing experience

72M+ Parts

We had finished

2300+ Clients

Over the world

99.9%

Satisfaction

What Is Rapid Prototyping?

Rapid prototyping means making a physical sample of a new product design idea. This is done as a preliminary step towards eventual production and is most useful when verifying that the finished product will look, feel, and perform as intended. New product developers turn to rapid prototyping for several reasons. They’re used for functional testing, approvals, design iterations, crowdfunding campaigns, trade show models, and as a bridge to low-volume manufacturing.

Prototypes often inspire re-designs, improvements, and other modifications that may not have been obvious merely from a computer graphic. In this regard, they’re beneficial for optimizing a design before committing resources to larger volumes. Correcting design errors early in the development phase can more than compensate for the cost of the prototype itself, so they’re wise investments.

Our Capabilities For Rapid Prototyping Machining

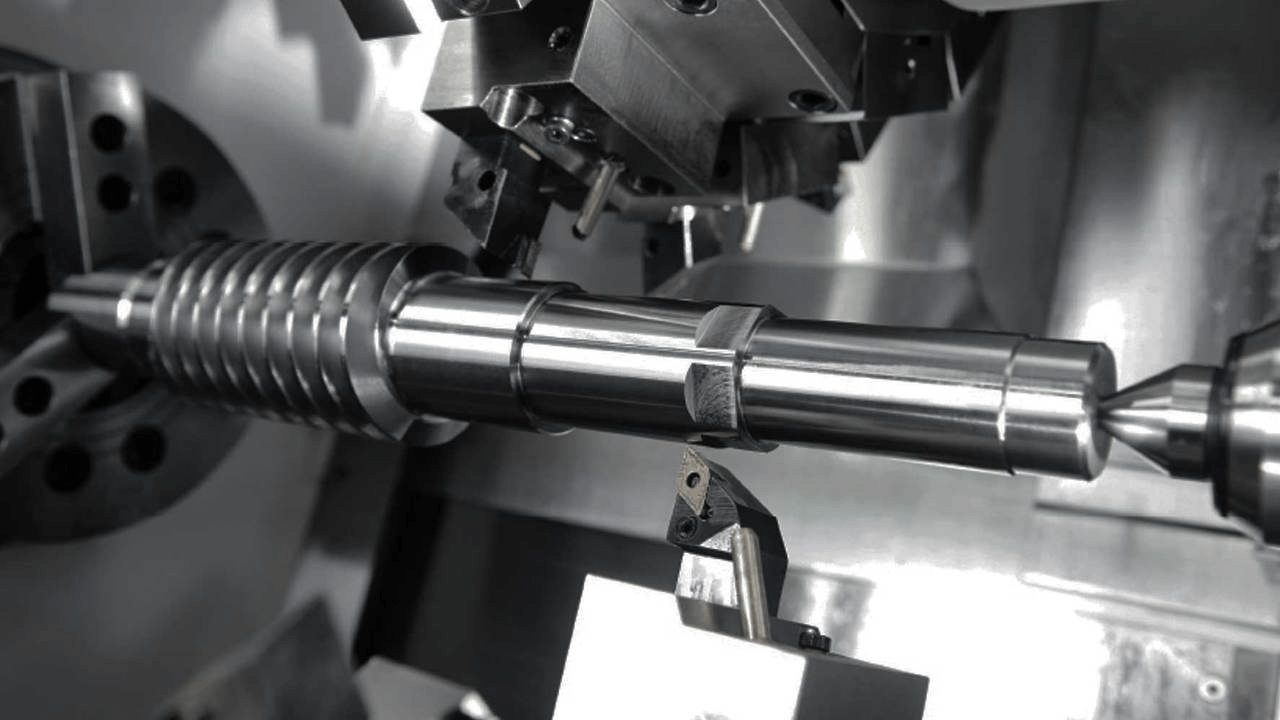

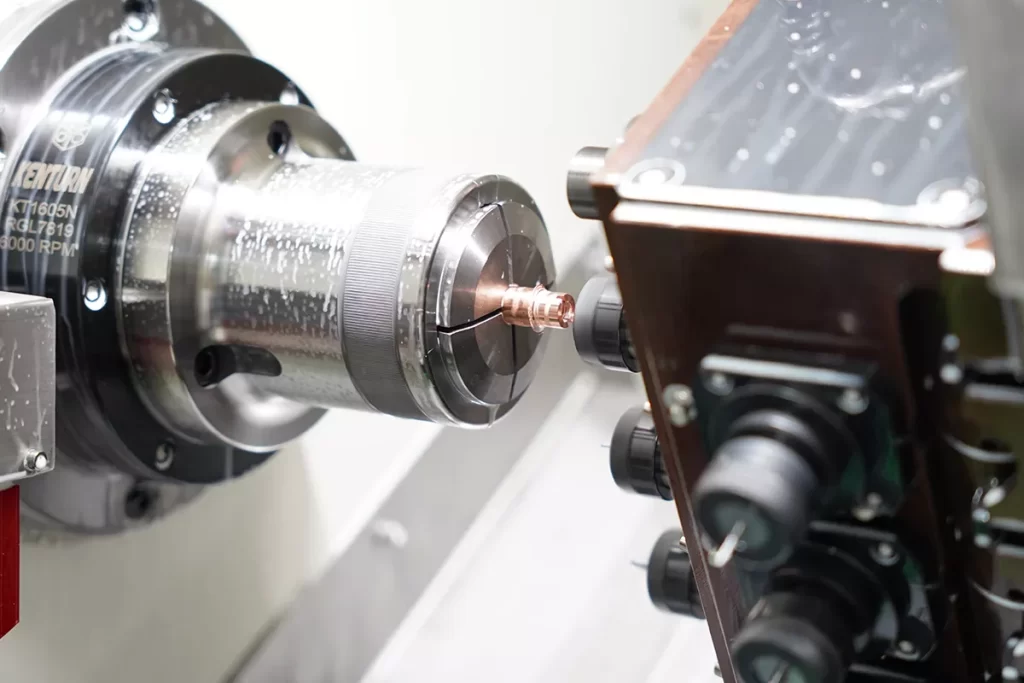

CNC milling and turning are great rapid prototyping options for parts requiring the prototype to be evaluated in its final material if cut from a fully dense stock. JCRAPID can machine a wide variety of metals and plastics. Many CNC-machined parts can be manufactured and shipped within a week. CNC expedited options are available when quoting, and JCRAPID cost-effective, market-based prices enable engineers to order multiple prototypes simultaneously to enable rapid product evaluation.

CNC Milling Prototyping Service

CNC Turning Prototyping Service

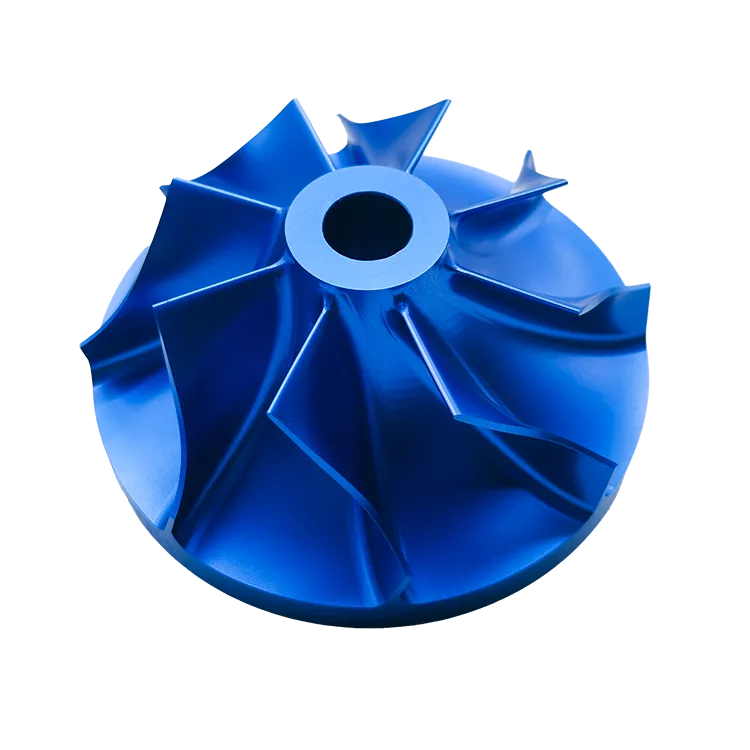

Gallery of Rapid Prototyping Parts

we have produced prototypes for various industries including medical, automotives, aerospace, construction, and other industries.

Rapid CNC Machining

For rapid prototyping of plastic and metal parts, CNC machining is the ideal production option, as we can create all the prototypes you need with precision detail and complete them within a short lead time.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm (+/- 0.001 inch) |

| Hole diameters (not reamed) | +/- 0.025 mm (+/- 0.001 inch) |

| Shaft diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Part size limit | 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch) |

Rapid Vacuum Casting

If you’re looking for a quick and reliable source of elastomeric plastic parts, JCRAPID has you covered. Our vacuum casting process offers high-quality, consistent plastic pieces with intricate and impressive details.

| Standard capabilities | Description |

|---|---|

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Dimensional accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

Get High-Quality Rapid Prototyping Machining With Efficiency & Speed

Our professionals and the team of experts are trained to provide you with the very best in minimum time and with high efficiency that makes us stand out from the crowd.

Not only do we provide various prototyping options, but we also make sure that you are getting exactly what you desired without a doubt!

What Are The Different Types Of Rapid Prototyping?

Any physical model could be a prototype. The difference lies in how closely it reflects the intended finished part.

Simple models can be made with paper, plastic, modelling clay, styrofoam, balsa wood, or other common household materials. These are examples of very low-fidelity prototypes, but they do have the advantage of being easy and inexpensive to make.

These prototypes would likely not function well or for long, so they’re used primarily to get a visual idea of the design and to compare it in scale to other parts.

More high-fidelity prototypes use modern machine tools and materials, including various 3D printing technologies, vacuum casting, rapid tooling for injection molding, and CNC machining.

Material Options for Rapid Prototyping

We provide quotations for over 100 metals and plastics for your prototyping needs. On our platform, you can also view the different materials and the cost of their machining.

Metals

There are different types of metals, each with different physical and chemical properties. These differences make some metals better suited to a particular application than others. The methods for producing metal prototypes include; CNC machining, Casting, 3D printing, and sheet fabrication.

| Brass | Titanium | Aluminum | Copper |

| Stainless Steel | |||

Plastics

Plastic is a broad term encompassing several materials. Most of them have favorable properties that make them ideal for rapid prototyping, including ease of molding, insulation, chemical resistance, wear resistance, and lightweight.

The methods for making plastic prototype parts include; urethane casting, 3D printing, and CNC machining.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Advantages Of Making A Prototype

How can making a prototype help you and your business? Here are just some of the ways:

1. Show your customers and investors a physical model of your product

2. Demonstrate the appearance, dimensions, and features of your product

3. Test the market with your product before production

4. Save time and money by identifying and reducing design flaws

5. Improve and streamline the production process

6. Create multiple versions with different colors, surface textures, and finishing processes

Why Choose JCRAPID For Your Next Rapid Prototyping Project

Making a quality prototype is an important first step in your product development journey. We’re veterans in rapid prototyping, and we can help you to make your design dreams come to life.

Low Cost

Keeping the main purpose of rapid prototyping machining under vision, we keep the packages and services pocket-friendly. You do not need to worry about a thing with the budget.

Excellent Quality

Under no circumstances do we compromise on quality, as it is the characteristic that makes us unique. With specialized machinery and material, Guaranteed to have the best from us.

High Precision

We believe that precision leads to successful masterpieces, and we provide that with ultimate accuracy and effort. We help your every need as your satisfaction is our top priority.

Industry-Leading Expertise

We’ve helped hundreds of clients, from private inventors to large corporations, create stunning prototypes that exceeded their expectations, and we can do the same for you.

Cutting-Edge Equipment

We’ve invested in the finest raw materials and equipment so you get superior rapid prototypes that look and perform like full-production parts, but in a fraction of the time and cost.

Quick Turnaround Time

As our name suggests, rapid prototyping machining will provide a quick turnaround time, and you can get your masterpiece as soon as you need without any hassle.

Quality is our top priority

“QUALITY COMES NOT FROM INSPECTION, BUT FROM IMPROVEMENT OF THE PRODUCTION PROCESS.”

We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

Our Rapid Prototyping for Various Industrial Applications

Many industries, such as the medical and food service sectors, rely on JCRAPID’s rapid prototyping capabilities to meet their growing demand for parts used on critical production equipment.

Get Pre-eminent Rapid Prototyping Machining Customized To Your Budget

We know the primary purpose of prototyping, and that is examining and analyzing the look of the product before you move on to the final project. Hence, we understand the need that you want to keep the budget according to your pocket.

That lead’s to the fact that here you can get premium service and packages customized to your budget and requirements.