CNC Machining Service

CNC Machined NPI prototypes and precision production parts expedited to meet your build time requirements

- Rapid prototyping and full-scale production

- Tolerances down to ±.0008’’ (0.020 mm)

- ISO-9001:2015 IATF 16949:2016 ISO 13485:2016

- Lead times from 5 business days

- Quotes for up to 10,000 parts

- 50+ metals and plastics, 20+ surface finishes

CNC Precision Machining Service

In case you were searching a trustworthy factory for precision CNC machining in China, you came to the right address. Your goal is probably to find the best CNC machining parts manufacturer who delivers quality components at an affordable cost? At JC RAPID, we use advanced 3 axis, 4 axis and 5 axis CNC equipment to offer you more than 60+ machined metals & plastics, our CNC machining services include CNC milling, CNC turning, EDM, and wire EDM, surface grinding, and much more.

JC RAPID adheres to the enterprise spirit of “high, precise and sharp” and continues to enhance the competitiveness of the company with the core value of casting the world brand with advanced technology. Design phase manufacturable technical support, manufacturing cost optimization at different stages, delivery of high quality parts.

10000+㎡

Area

100+

Employee

20

Years Of Operation

3000+

Customer

Our CNC Machining Services

Our high-speed machining centers are equipped to offer automated precision machining services with fast quotes and short lead times. As a full-service CNC machine center, JCRAPID confidently accommodates the needs of our clients whether quoting an existing design or designing something from scratch. JCRAPID’s extensive machining capabilities, years of experience, and state-of-the-art technology, allows your project to be completed quickly and efficiently to the tightest of tolerances.We are experienced in working with a variety of metal and plastic materials including aluminum, Mild steel, Alloy steel, Brass, Copper, Bronze, Stainless steel, and titanium.

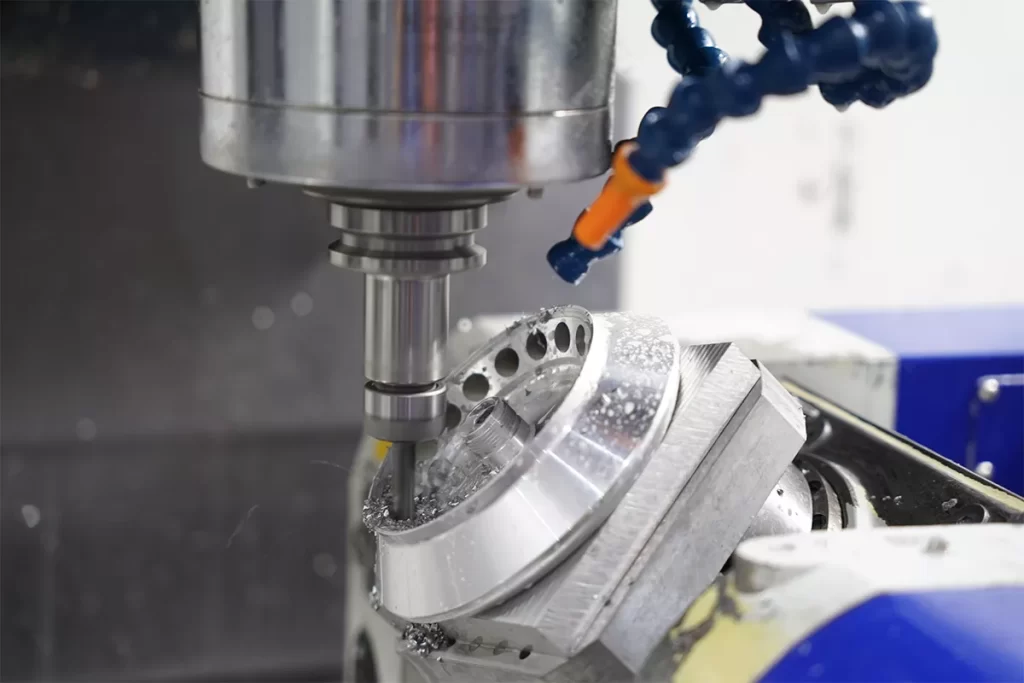

CNC Milling

During CNC milling, the workpiece is held stationary directly on the machine bed or in vise, material is removed from the workpiece using specialized cutting tools that rotate at a very high speed. WIth our 3-axis, 4-axis & 5-axis CNC machines, you can get milled parts with tight tolerance up to 0.01mm (±0.0004 in.)

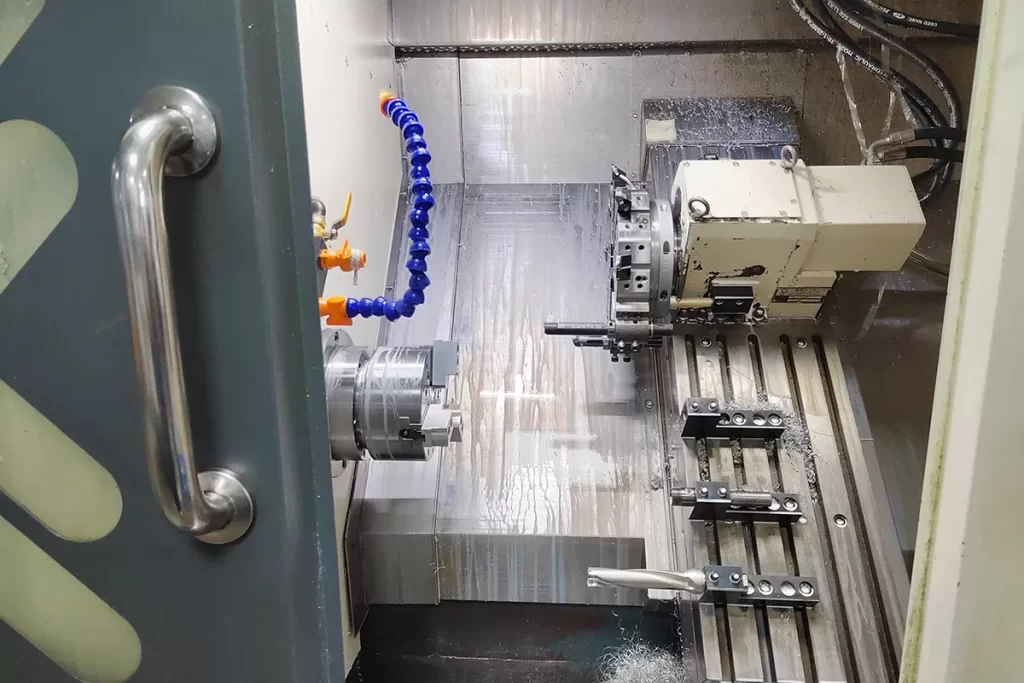

CNC Turning

CNC turning can produce parts with a cylindrical profile at a much higher rate and a lower cost per unit than CNC milling. During CNC turning the workpiece is held on the spindle while rotating at high speed, a Cutting tool traces the outer an inner perimeter forming the geometry.

Standard Tolerances for CNC Machining in JCRAPID

Precision is key in many industries. If you have a product that must fit with or in another part to create a finished part, then machined tight tolerances are imperative. CNC machined product adheres to the measurements needed for processes after order completion.Sure thing is we can provide more tighter tolerance as well, if you have special requirements, please contact us.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

| 0.5 mm* to 3 mm | +/- 0.1 mm | +/- 0.05 mm |

| 3 mm to 6 mm | +/- 0.1 mm | +/- 0.05 mm |

| 6 mm to 30 mm | +/- 0.2 mm | +/- 0.1 mm |

| 30 mm to 120 mm | +/- 0.3 mm | +/- 0.15 mm |

| 120 mm to 400 mm | +/- 0.5 mm | +/- 0.2 mm |

| 400 mm to 1000 mm | +/- 0.8 mm | +/- 0.3 mm |

| 1000 mm to 2000 mm | +/- 1.2 mm | +/- 0.5 mm |

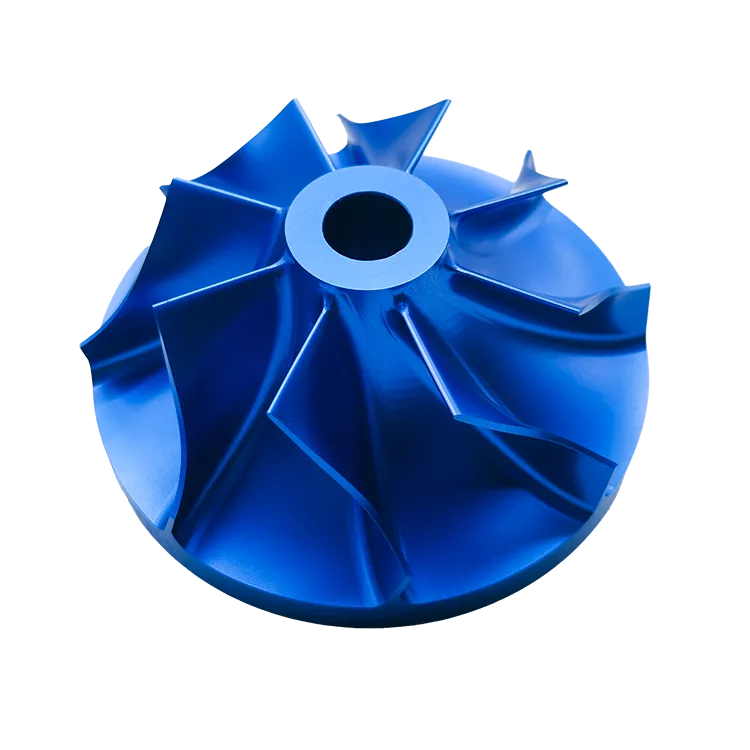

Machining Examples - From Single Parts...to Complex Assemblies

The gallery showcases precision machined prototypes and parts from our valued customers.

Materials for Custom CNC Machining Parts

Materials used for custom CNC machining will vary by application. The precision of our process is certainly able to handle many types of materials. The cost of certain types of material, such as plastic is less expensive to purchase. Depending on the use of the product a stronger material, such as metal, may need to be used. Thus, we machine a wide array of materials.

| METALS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE | Common Grade Of Materials |

| Stainless Steel | 1-1000 | (+/-)0.002 |

|

|

SS303,SS303F,SS304,SS316,SS316L, SS440,SS420,SS430,SS440,SS630,17-4PH |

| Alloy Steel | 1-1000 | (+/-)0.002 |

|

|

SAE1010, SAE1020, SAE1040, SAE1045, SAE4340, A366/CQ, A36, GR60, D-2, 12L14, 50C4V2 |

| Aluminum | 1-1000 | (+/-)0.002 |

|

|

AL1050, AL2024,A360, AL4643,AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, AL7050 |

| Copper/Brass/Bronze | 1-1000 | (+/-)0.002 |

|

|

C11000, C10100, C1720, C21000, C27200, C3710, C51900, C51900,C5210, C6301 |

| PLASTICS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE | |

| HDPE | 1-100 | (+/-)0.005″ |

|

|

|

| PC | 1-100 | (+/-)0.005″ |

|

|

|

| ABS | 1-100 | (+/-)0.005″ |

|

|

|

| PMMA(Acrylic) | 1-100 | (+/-)0.005″ |

|

|

|

| Nylon 6/6 | 1-100 | (+/-)0.005″ |

|

|

|

| POM(Acetal Delrin®) | 1-100 | (+/-)0.005″ |

|

|

|

| Polyetherimide(ULTEM®) | 1-1000 | (+/-)0.005″ |

|

|

|

| PEEK | 1-1000 | (+/-)0.005″ |

|

|

|

| PTFE | 1-1000 | (+/-)0.005″ |

|

|

Trusted CNC Machining Services

Count on us to provide you with CNC machining services to facilitate your project seamlessly. Our qualified professionals can assist you with turning services, machining services, and more. Our CNC turning services and CNC milling services are second to none.

Wide Range of Surface Finishes for You

Choose multiple surface finishes for your machined parts. Add finishes to protect your custom CNC parts from harsher environments.

| As-Machined | We can hold machined surface roughness tolerance from 3.2 – 16 mm. This does not provide a protective barrier to environmental effects such as rusting. |

| Anodized | There are varying types of anodized. This is a colored finished and the chosen will define the type. |

| Powder Coat | This is more resistant to chipping than regular paint. The color is retained and the powder coat has much thicker layers than wet paints. |

| Passivation | This finish uses nitric or citric acid and removes free iron from the surface. It protects the surface with a chemical for functions as a rust preventative. |

| Titanium Anodize | This surface finish changes the oxide layer in a titanium surface using an electric current. If it is not treated after machining, it will create titanium dust when rubbed together. |

| Electropolishing | This provides a brighter finish for the machined surface. It is used to polish or deburr metal parts. |

| Electroplating | Electroplating is the process of applying a thin layer on the surface of the part. Electroplating can improve the corrosion resistance, wear resistance and appearance of the parts. There are different types of plating, including nickel plating, chrome plating and gold plating. |

| Heat treating | Heat treating can improve CNC parts hardness, strength, and toughness and other mechanical properties. Common heat treatments including AnnealingTempering, Hardening, high frequency heating, stress relieving and so on. |

Why choose JCRAPID?

ISO 9001 Accredited

Our commitment to the highest quality parts is demonstrated through our ISO 9001 certification

Superior Customer Service

Tired of manufacturers not responding to your quote requests? We aim to get back to you within minutes, not days.

Vast Flexibility

We’re proud not to be an automated platform, therefore we can manufacture complex projects that others simply cannot.

Competitive Pricing

We’re lean and efficient and pass those cost savings on to you. Our network of partner factories ensures that we source the best prices for your projects.

Fast Turnaround

From the initial quote to delivered parts, we work quickly to ensure your ideas and projects are brought to market quickly and on-time.

Applications of CNC Machining Process

The applications of CNC machining are in various industries. This technology is used directly or indirectly in almost every industry imaginable, such as Medical Industry, Aerospace and Drone Industry, Automotive Industry, Electronics Industry, Military, Defense Industry, Green Energy Industry, 5G communication Construction, and Architecture. In JC Rapid, some types of CNC machining methods can meet any manufacturing requirements and custom orders as required.

Jcrapid CNC Machining Service FAQ

CNC machining is fast, accurate, and versatile. No other manufacturing solution produces end-use parts in any volume without investing in hard tooling or expensive set-ups.

Almost any rigid solid can be machined, including mild and stainless steel, aluminum, brass, copper, magnesium, titanium, and many engineering plastics. Check out our list of frequently used materials.

Our standard tolerances are 0.05 millimeter, suitable for most commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

At JC RAPID, we offer CNC milling (3-axis, 4 axis, 3+2-axis, and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 200 mm (78.7 x 59.0 x 7.8 in.) For 3+2 axis and 5-axis milling, the maximum part size is 350 x 350 x 300 mm (13.8 x 13.8 x 11.8 in.). The maximum diameter for CNC turning is 431 mm (17 in.), length is 990 mm (39 in). The minimum part dimensions recommended are around 0.39 x 0.39 x 0.39 in. (10 x 10 x 10 mm). The minimum for feature dimensions is 0.5 mm. We are limited to a 1000 mm (39 in.) maximum size for parts on our platform. You can place the request through your account manager if you need higher dimensions.

We perform full rang of CNC machining services, which including CNC milling, 5-axis CNC milling, turning and Swiss screw machining.

If your parts are low-volume production quantities and you need fast lead times, for example Volume: 50-2,000+ parts, then you are in the right place.Contact us to get your cnc rapid prototyping projects started today.