Contrary to other traditional manufacturing methods, precision CNC manufacturing can transform how various industries work, allowing for cost savings while also boosting productivity, tightening tolerances, and offering a more dependable manner of making components.

Since its invention, precision CNC machines have been a go-to option for most manufacturing industries worldwide. They are still used as manufacturing processes develop, fueled by new materials ranging from metals to plastics. Precise CNC machines can create almost any product or form requested, including custom sizes. Their capabilities may be observed in the automotive sector, where they are built into each new model. And they’re not just for automotive space; precision CNC is also used in aerospace, health, marine, heavy equipment, defence, and many more. So, why is precision CNC a good fit in contemporary manufacturing today? Read on to learn more.

What is Precision CNC Machining?

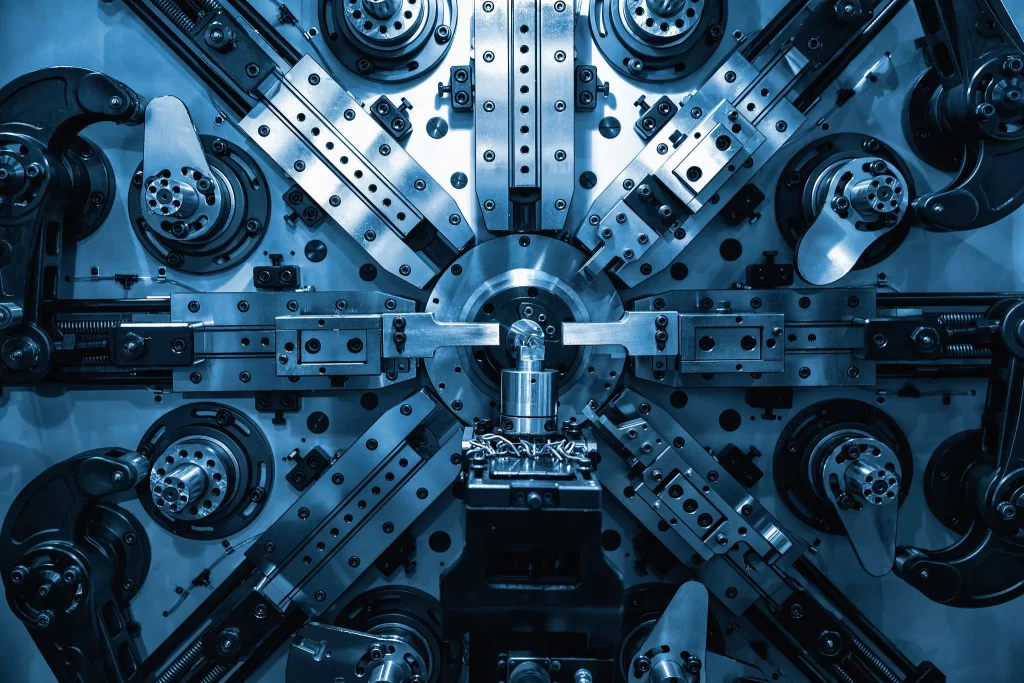

Precision CNC Machining is the technique of precisely cutting diverse materials. This procedure often entails removing extra material from a metal component (or other material) and reshaping it to a high tolerance level. To put it another way, precision machining is the process of reshaping a huge portion of a material into smaller, more refined bits.

Precision CNC machining creates things of various sizes that we utilize daily. In reality, all the equipment and ordinary household objects you use need some degree of CNC machining process. Precision machining is used to manufacture anything from automobiles and medical equipment to hair-styling gadgets and household appliances.

CNC precision can manufacture extremely tight tolerance components with a high degree of part complexity, often ranging from 0.0002″ to 0.0005″. It is possible to produce extraordinarily smooth surface finishes in addition to tight repeatable tolerances. Much of the accuracy and better surface finishes are due to advancements in servo control technology.

Why Do We Require Precision CNC?

There are several reasons why CNC precise machining is crucial in today’s industrial manufacturing. Some of the most important factors are often considered:

Getting Rid of Human Errors & InconsistenciesWhen you create a component or product by hand or using traditional techniques, you can’t reach the same level of consistency and precision that CNC machines can. CNC machines make and copy many almost identical items (with an average variance of less than 0.020mm—sometimes as small as 0.002mm) using design software, accurate model references, and fine-tuned precision tools. Even the most modern conventional machines are incapable of reproducing these outcomes.

This implies that the finished product will be incredibly consistent. This is a significant benefit in businesses where great uniformity is important (such as the automotive, dental, aerospace, and medical industries). It’s also essential for businesses to create sophisticated equipment or gadgets that need multiple pieces to fit together correctly. Any difference in shape, size, or texture might cause the finished product to malfunction. With Precision CNC machinery, you can create practically anything and repeatedly recreate it—even if it is intricate and detailed.

Enhancing the Manufacturing Process

As opposed to manual production or traditional machinery, CNC equipment does not need an engineer to run or monitor the operation. Most CNC machines run autonomously without engineers’ direct input or direction. The machine is ready to use as soon as it gets instructions from the computer and the manufacturer supplies the raw ingredients. This implies you can make components considerably quicker since there is no human work or downtime. Some devices can even run continuously.

Making use of fewer resources

Using CNC precision technology can maximize resources at every level of product development. In the early phases, a professional engineer or programmer is all that is required to develop a digital model of the design and program of the machine. When it comes to manufacturing, the CNC machine is mostly self-sufficient. It may also be configured to decrease waste and utilize just the raw material required.

Increasing Manufacturing Efficiency Over Time

Utilizing fewer resources and labour results in cost reductions. You can either reinvest the savings in additional components or lower the retail price of your finished product to gain a competitive edge and attract more customers. You’ll also save money on overhead when you outsource your product design to a full-service CNC equipment supplier. The manufacturer obtains software licenses and equipment, maintains or replaces machines and cutting tools, and recruits personnel to supervise the operation. You will only be charged for the final results.

Expanding Production

Finally, using CNC machinery provides you with more manufacturing options. You can begin with a small batch of high-quality components. Later, if there is a huge demand for your product or you need to scale up to corner the market swiftly, producing extra components using a CNC machine is relatively simple. Furthermore, whether you’re making a few parts or thousands, the quality and consistency of your products remain the same. You can determine how many components you need at any given time and decrease surplus inventory.

Recreating a portion, even years after you initially created it, is also quite simple. You may return to the design as much as possible if it is safely kept in the CNC program.

With so many benefits to employing CNC technology in production, it’s a choice that every product designer and company owner should think about.

Conclusion

Precision manufacturing has significantly impacted several sectors, including transportation, aerospace, healthcare, etc. As more businesses find ways to use this technology, its influence will grow. To sum up, a seasoned service provider offering CNC precision manufacturing can make almost any idea a reality while adhering to strict tolerances, keeping client budgets in check, and following production schedules.