CNC Milling Service

Looking for top-quality precision CNC milling services? Our expert team provides precise and reliable milling and turning services to meet all your machining needs. Contact us today to see how we can help you! Get a quote today!

- Professional service from 10 to 1000+ parts

- Top team at your service

- Quality guaranteed – Shipping worldwide

- 50+ materials and 10+ surface finishes

CNC Milling Service for Your Custom Parts

Our China based CNC Machining Centre of Excellence offers an unparalleled level of quality and precision. From one off prototypes through to high volume production, we continue to produce complex components to meet the increasing demands of our customers.

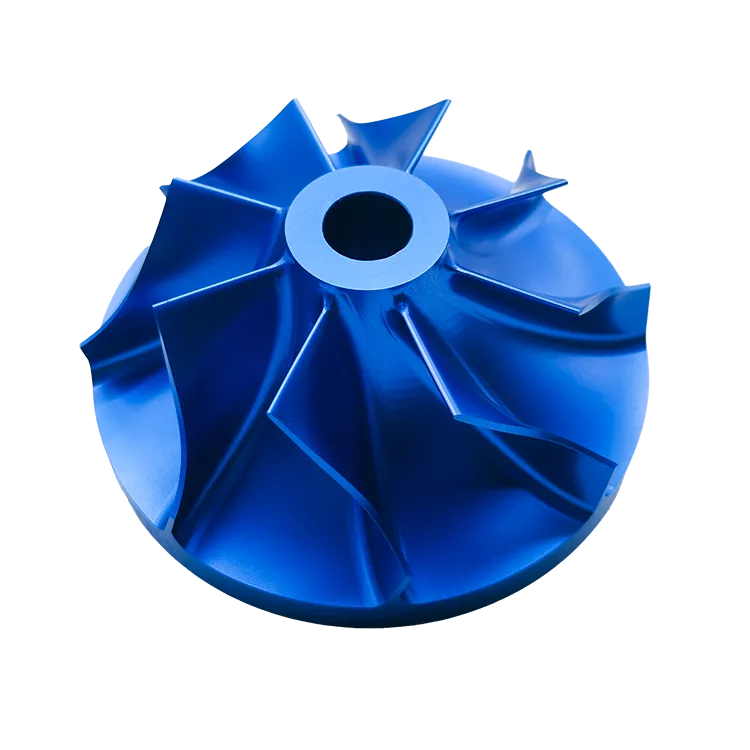

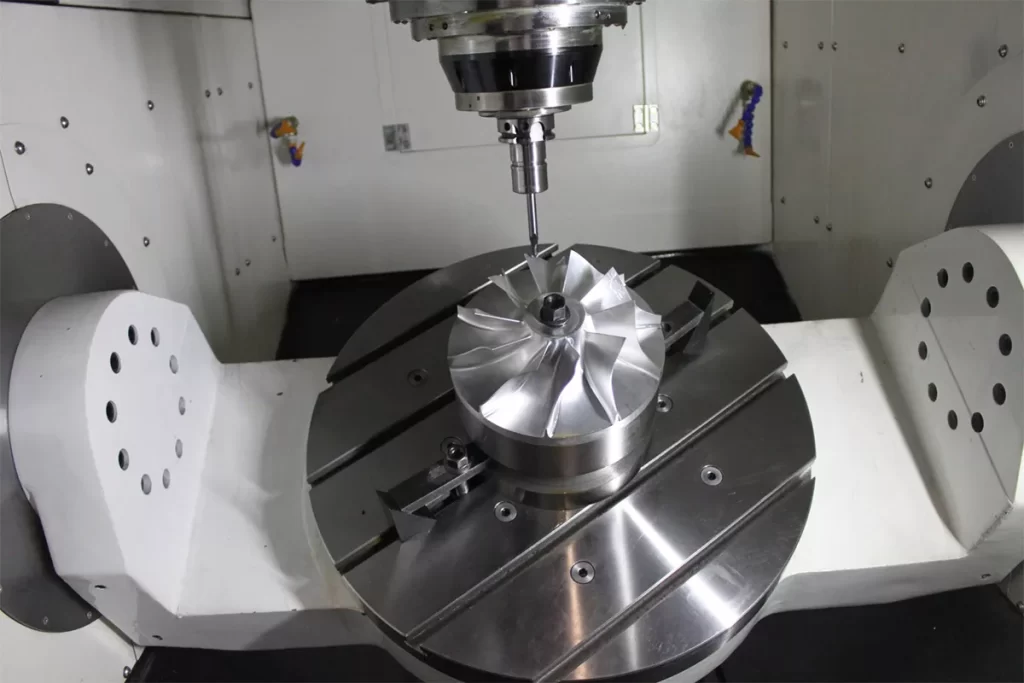

With 3, 4 and 5 axis CNC Milling capabilities, JCRAPID can produce complex engineered components at a competitive price. We regularly machine components from a wide range of materials including Aluminium, Brass, Carbon Steels, Copper, Mild Steel and Stainless Steel.

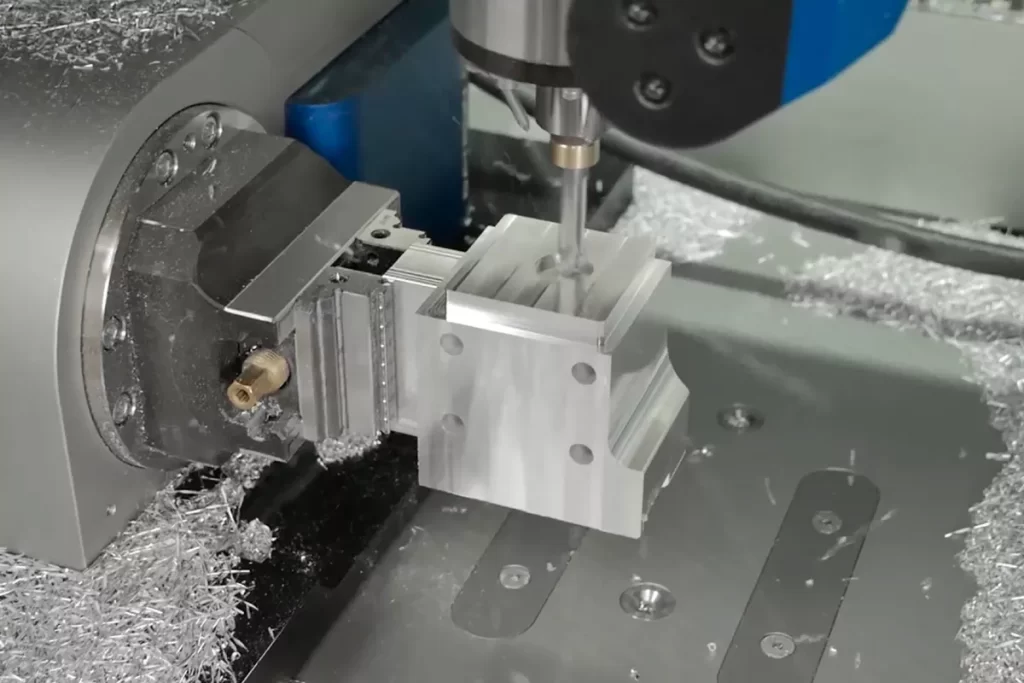

Our dedicated team of engineers are equipped with the latest advancements in high precision CNC Milling machines, cutting tools and work holding equipment. Combined with the latest advancements in CAM software, we are able to achieve a tolerance of +/- 0.02mm on complex geometries.

CNC Milling Processes

3-axis CNC milling

The most widely used type of CNC milling machine. The full use of the X, Y, and Z directions makes a 3 Axis CNC mill useful for a wide variety of work.

4-Axis CNC machining

This type of router allows the machine to rotate on a vertical axis, moving the workpiece to introduce more continuous machining.

5-Axis CNC machining

These machines have three traditional axes as well as two additional rotary axes. A 5-axis CNC router is, therefore, able to machine 5 sides of a workpiece at in one machine without having to remove the workpiece and reset.

Our Capabilities

| Main production Equipment | 10 sets of precision 5-axis machines, 30 Advance Milling Machine for rapid prototype, 30 Advance Milling Machine for CNC low volume manufacturing, 20 CNC Lathes machine, 2 Grinding Machine,4 EDM machine,1 laser cuting machine,2 pending machine, 3 Tapping Machine, |

| Main Process | CNC turning, CNC milling, complex CNC turning and milling, 5-Axis machining, Gear machining, Sand Blaster process,and other processing technologies and 25 kind of finished such as :Anodised ,Powder coated,Electroless Plating,Black oxide etc. |

| Main Industry | Design industry .Robotics industry, Prototype, Medical device, aerospace parts, Auto parts, Electronics Industry etc. |

| The best tolerance | 0.005mm |

| Largest turning size | Φ600mm |

| Largest size milling | 2000*700*1000mm |

| Main QC test Equipment | CMM, Microscrope, XRF Analyzer,Hardness tester,Height gauge,Digital Slide,Tool detection,Pin Gauge.Thread Ring Gauge. etc |

Request Your Free CNC Milling Quote

If your company needs a CNC Milling parts supplier who can handle the most detailed orders with expert craftsmanship in a short turnaround time, JCRAPID is your number one choice.

Why Choose CNC Milling?

CNC milling is ideal for making angled shapes, slots and channels, chamfers, holes, curves and flat surfaces, among many other features. A CNC mill removes large amounts of material fast with high accuracy, while producing a good surface finish. Milling can be done on any rigid material, though we primarily work with metals and plastics. Of all available CNC machining processes, milling is the most versatile.

Milling is used not only to make finished parts but also to build tooling for plastic injection molding and pressure die casting. Set-up time is minimal, so a CAD file can be translated into a finished part in a matter of hours. Because there is no need to make other specialty tools, you aren’t committed to a minimum order quantity so the process is very cost effective with little waste.

CNC milling applications

From single, speciality parts to full production runs, CNC milling can be used to create a variety of industrial parts with applications that include:

Tooling

Manufacture parts with complicated cuts and different angles using a variety of cutting, drilling, and lathing tools.

Niche manufacturing

CNC milling is capable of creating a range of niche, durable metal or plastic products that alternative manufacturing processes cannot.

Medium-to-high-volume production

The CNC milling process is particularly useful for high-volume manufacturing runs, offering automated speed and cost benefits.

Metal fabrication

CNC milling is a safe, effective way of creating high quality metal parts with exceptional tolerance levels.

Hybrid manufacturing

CNC milling is not just a process suited to working with metals: molded and 3D printed parts can also be machined.

Rapid prototyping

The CNC milling process is fast, automated, and useful for the production of prototype parts.

CNC Milling Materials Available

As one of the leading manufacturers, JCRAPID offers both metal CNC machining and plastic CNC machining. Materials available for CNC milling include:

| METALS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE |

|---|---|---|---|---|

| Stainless Steel | 1-1000 | +/- 0.005″ |

|

|

| Low Carbon Steel | 1-1000 | +/- 0.005″ |

|

|

| Aluminum | 1-1000 | +/- 0.005″ |

|

|

| Brass | 1-1000 | +/- 0.005″ |

|

|

| PLASTICS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE |

| HDPE | 1-100 | +/- 0.008″ |

|

|

| PC | 1-100 | +/- 0.008″ |

|

|

| ABS | 1-100 | +/- 0.008″ |

|

|

| Acrylic | 1-100 | +/- 0.008″ |

|

|

| Nylon 6/6 | 1-100 | +/- 0.008″ |

|

|

| Acetal (Delrin®) | 1-100 | +/- 0.008″ |

|

|

| ULTEM® | 1-100 | +/- 0.008″ |

|

Our standard surface finishes

Here is a list of standard surface finishes. For custom surface finishes such as electroplating or polishing, please contact engineers@jcrapid.com.

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | Learn More>> |

|

Bead Blasting |

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. |

ABS, Aluminum, Brass, Stainless Steel, Steel

|

n/a | Matte | Learn More>> |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel |

Black, any RAL code or Pantone number

|

Gloss or semi-gloss

|

Learn More>>

|

|

Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. |

Aluminum, steel, stainless steel

|

n/a

|

Smooth, glossy finish

|

Learn More>>

|

|

Polishing |

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

|

Aluminum, Brass, Stainless Steel, Steel

|

n/a

|

Glossy

|

Learn More>>

|

|

Brushing |

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. |

ABS, Aluminum, Brass, Stainless Steel, Steel

|

n/a | satin |

Learn More>>

|

What Are The Advantages of Jcrapid CNC Milling Service?

- Imported CNC milling centers and cutting tools offer repeatable precision on your projects.

- Staffed by skilled operators working with a team of international managers and toolmakers.

- We’re able to keep costs down while providing unmatched precision and quality without compromises.

- We work in a clean, well-lit and climate-controlled production area, certified to ISO9001:20015, ISO14001 and BS-OHSAS 18001 standards.

- We use best-in-class AutoCAD software for maximum efficiency and machine compatibility.

- Incoming quality inspection and testing of raw materials ensures the integrity of our supply chain, so you get exactly the materials you specified.

- We are experts in prototyping and low-volume manufacturing, so quick set-ups and rapid production is in our DNA.

- Our CNC milling services are designed to work in tandem with our many other in-house fabricating and finishing capabilities, to provide you with a comprehensive one-stop rapid manufacturing solution.

- We’re located close to major shipping ports in Shenzhen and Hong Kong, so your parts can be on their way to you fast.

Our CNC Milling for Various Applications

There are diverse applications of CNC milling parts- both plastic and metal. Here are some application areas.

Get Your CNC Milling Project Started Today

With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements. Contact us today for a free quote!