CNC Machining Service

Get high-quality CNC-machined metal and plastic parts with fast turnaround times. From rapid prototypes to full-scale production, we deliver reliable CNC machining solutions tailored to your needs.

- ISO 9001:2015, IATF 16949:2016, ISO 13485:2016 certified

- Over 50 metals and plastics, 20+ surface finishes available

CNC Machining Capabilities

At JC RAPID, we specialize in high-precision CNC machining, utilizing 3-axis, 4-axis, and 5-axis equipment to meet your needs. We offer expertise in CNC milling, turning, EDM, wire EDM, and surface grinding, with the ability to process a wide range of metals and plastics.

From the design phase to production, we collaborate closely with you to optimize parts for manufacturability, reducing both costs and waste.

Why Choose JCRAPID?

Instant, Transparent Quotes

No more waiting. Upload your design and receive an instant, transparent quote with lead times. No hidden fees, no surprises—just clear and reliable pricing.

Customer-Centric Support

Our team is committed to your success, offering expert support at every step. From design to delivery, we ensure your project is on track and meets your expectations.

High-Quality Standards

Every part we produce meets the industry standards. Our ISO-certified processes ensure that your custom parts are manufactured with accuracy, durability, and reliability.

Fast Turnaround

We understand the urgency of your projects. With rapid prototyping and fast production times, we deliver custom parts when you need them—without compromising on quality.

What Our Customers Say

We are truly grateful to our clients for their trust and thoughtful feedback.

The team provided clear communication throughout the project, from design to production. They really took the time to understand our needs and offered valuable insights into improving our designs. The machining quality is reliable. We look forward to continuing this collaboration.

John K.

CEO

We’ve worked with JCRapid on multiple CNC machining projects, from small batches to large production runs. Their commitment to quality and on-time delivery is unmatched. Their team’s transparency and communication make every collaboration seamless.

Michael W.

CEO

We were impressed by the precision and consistency of the parts we received. JC Rapid’s CNC machining services exceeded our expectations. The tolerances were spot on, and the finish was flawless. Highly recommend for anyone needing high-quality machining!

John D.

Project Manager

What sets JC RAPID apart is their attention to detail and expert design feedback. The DFM suggestions we received saved us both time and cost during production. Truly a team of professionals who care about customer success.

Sarah L.

Project Engineer

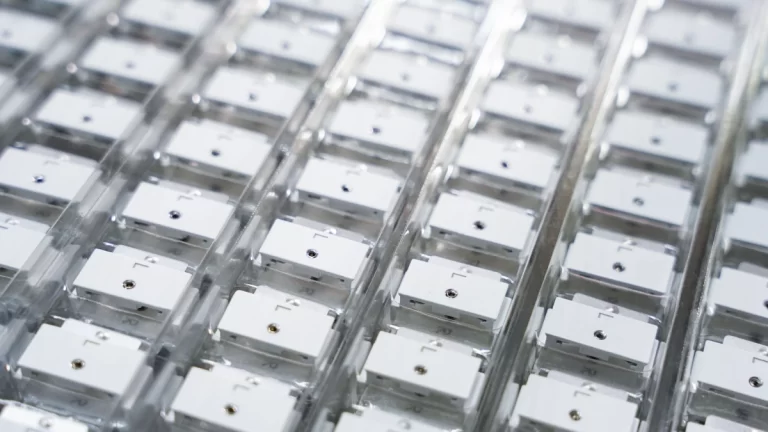

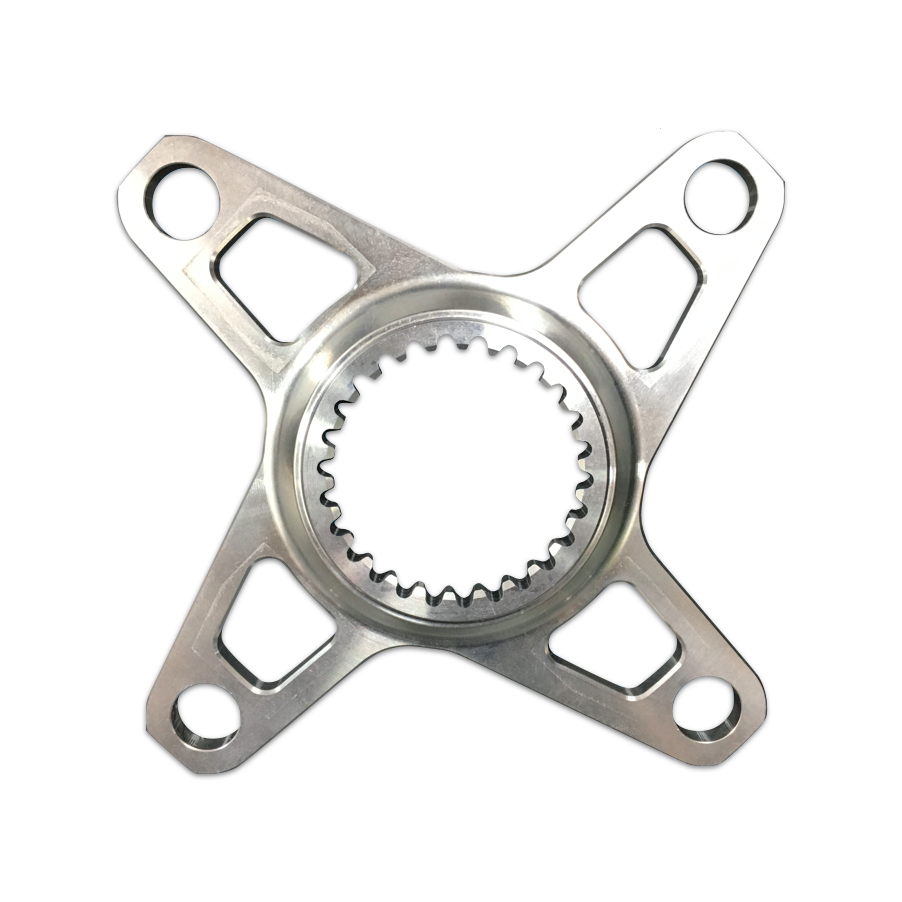

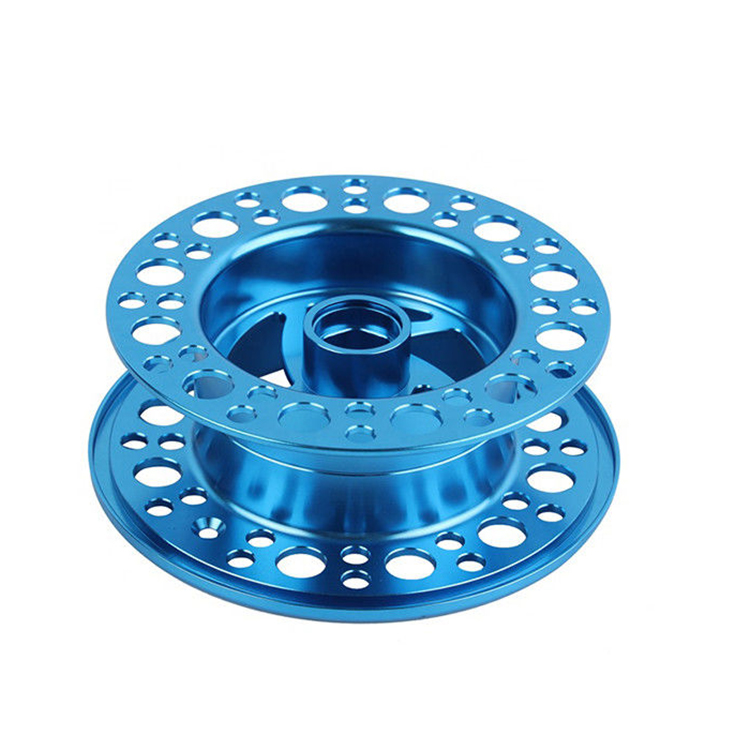

Machining Examples

Explore our gallery of precision-machined parts, demonstrating the quality and versatility of our CNC services.

Our CNC Machining Process

From design to delivery, all in one place. We can manufacture and manage your parts flexibly and cost effectively.

Upload Your Design

Upload your CAD files or drawings directly to our platform. We’ll process it and provide pricing and lead times.

Design Review & Feedback

Our engineers will review your design, provide manufacturability feedback (DFM), and ensure it meets production standards.

Production & Machining

Once approved, we begin the CNC machining process using advanced equipment to deliver precise, high-quality parts.

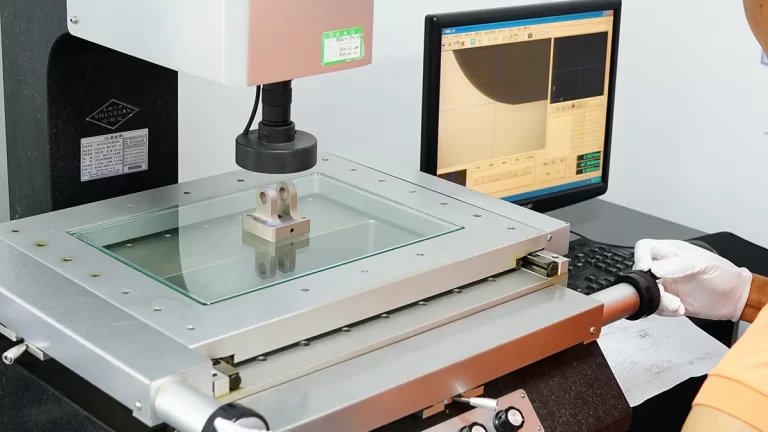

Quality Control & Delivery

Your parts undergo thorough quality checks before being shipped on time, meeting all specifications and standards.

Applications of CNC Machining

Medical, Architecture, Consumer, Electronics, Automotive…

CNC Machining Service FAQs

Choose multiple surface finishes for your machined parts. Add finishes to protect your custom CNC parts from harsher environments.

| As-Machined | We can hold machined surface roughness tolerance from 3.2 – 16 mm. This does not provide a protective barrier to environmental effects such as rusting. |

| Anodized | There are varying types of anodized. This is a colored finished and the chosen will define the type. |

| Powder Coat | This is more resistant to chipping than regular paint. The color is retained and the powder coat has much thicker layers than wet paints. |

| Passivation | This finish uses nitric or citric acid and removes free iron from the surface. It protects the surface with a chemical for functions as a rust preventative. |

| Titanium Anodize | This surface finish changes the oxide layer in a titanium surface using an electric current. If it is not treated after machining, it will create titanium dust when rubbed together. |

| Electropolishing | This provides a brighter finish for the machined surface. It is used to polish or deburr metal parts. |

| Electroplating | Electroplating is the process of applying a thin layer on the surface of the part. Electroplating can improve the corrosion resistance, wear resistance and appearance of the parts. There are different types of plating, including nickel plating, chrome plating and gold plating. |

| Heat treating | Heat treating can improve CNC parts hardness, strength, and toughness and other mechanical properties. Common heat treatments including AnnealingTempering, Hardening, high frequency heating, stress relieving and so on. |

Our standard tolerances are +/- 0.02 millimeter, suitable for most commercial and industrial applications. Tighter tolerances available upon request.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

| 0.5 mm* to 3 mm | +/- 0.1 mm | +/- 0.05 mm |

| 3 mm to 6 mm | +/- 0.1 mm | +/- 0.05 mm |

| 6 mm to 30 mm | +/- 0.2 mm | +/- 0.1 mm |

| 30 mm to 120 mm | +/- 0.3 mm | +/- 0.15 mm |

| 120 mm to 400 mm | +/- 0.5 mm | +/- 0.2 mm |

| 400 mm to 1000 mm | +/- 0.8 mm | +/- 0.3 mm |

| 1000 mm to 2000 mm | +/- 1.2 mm | +/- 0.5 mm |

We work with a variety of plastic materials including ABS, Nylon, Polycarbonate, and Delrin, ideal for custom parts.

| PLASTICS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE |

| HDPE | 1-100 | (+/-)0.005″ |

|

|

| PC | 1-100 | (+/-)0.005″ |

|

|

| ABS | 1-100 | (+/-)0.005″ |

|

|

| PMMA(Acrylic) | 1-100 | (+/-)0.005″ |

|

|

| Nylon 6/6 | 1-100 | (+/-)0.005″ |

|

|

| POM(Acetal Delrin®) | 1-100 | (+/-)0.005″ |

|

|

| Polyetherimide(ULTEM®) | 1-1000 | (+/-)0.005″ |

|

|

| PEEK | 1-1000 | (+/-)0.005″ |

|

|

| PTFE | 1-1000 | (+/-)0.005″ |

|

|

Our CNC services support metals such as aluminum, stainless steel, titanium, brass, and more, tailored to your project needs.

| METALS | OPTIMAL QUANTITY | TOLERANCES (+/-) | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE | Common Grade Of Materials |

| Stainless Steel | 1-1000 | (+/-)0.002 |

|

| SS303,SS303F,SS304,SS316,SS316L, SS440,SS420,SS430,SS440,SS630,17-4PH |

| Alloy Steel | 1-1000 | (+/-)0.002 |

|

| SAE1010, SAE1020, SAE1040, SAE1045, SAE4340, A366/CQ, A36, GR60, D-2, 12L14, 50C4V2 |

| Aluminum | 1-1000 | (+/-)0.002 |

|

| AL1050, AL2024,A360, AL4643,AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, AL7050 |

| Copper/Brass/Bronze | 1-1000 | (+/-)0.002 |

|

| C11000, C10100, C1720, C21000, C27200, C3710, C51900, C51900,C5210, C6301 |

Get Your Instant Quote Today

- Your privacy is our priority. If needed, we are happy to formalize this with an NDA before proceeding with a quotation.