If you recently come up with product designs and drawings for a new prototype, or do you need to manufacture a new part that requires machining? If so, you might decide to outsource your manufacturing to a third-party CNC machining service provider.This article covers everything you need to know about quality control in CNC machine shops. It will serve as a guide to help you quickly identify machine shops you should work with and those you must avoid.

Certifications are Essential

When gathering information about any machining vendor you’re considering, you must first access the certifications they’ve obtained. A crucial certification you must look for is ISO9001:2015 or need others like IATF16949:2016 and ISO13485:2016. ISO 9001 is a standard that specifies the requirements for quality management systems. An ISO 9001 certified machine shop adheres strictly to statutory and regulatory requirements by ensuring high-quality machining services.

Once you verify that the machine shops’ certifications meet your requirements, you must then determine the type of CNC machining equipment they have in their facility.

The Type of Machining Equipment Affects the Quality of Machined Parts

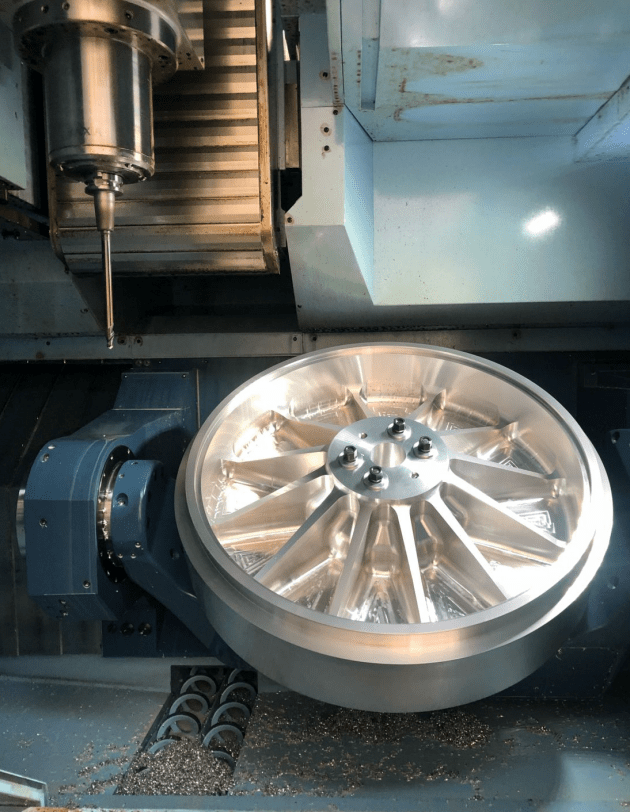

The type of CNC machines used to create prototype (or production) parts plays a significant role in the quality of parts you’ll receive. CNC machines come in many varieties and are typically classified by the number of axes they can operate within, for example, 2-, 3-, 4- and 5-axis CNC machines.

As one may imagine, 5-axis CNC machines are more advanced than 2-, 3-, and 4- axis CNC machines. They offer better relational accuracy, surface finish, and, more importantly, can machine complex shapes. Not all parts require 5-axis machining (like the one pictured above), but if a part is complex enough, it could be the ideal solution.

Third-party machining vendors that incorporate advanced CNC machining technology in their facility seek to ensure high-quality machined parts. But that’s not all you should look out for in a third-party machining vendor!

The quality of machined parts also largely depends on the level of expertise of the CNC operators that will be fabricating your parts.

Quality CNC Machining Depends on the Technician Operating the Machine

There have been many horror stories of customers receiving low-quality and unusable CNC machined parts, even though the manufacturer boasted about certifications and state-of-the-art machining equipment. More often than not, these issues are traced back to the CNC machine operators.

The truth is that there is a skill gap for CNC machine operators. The machining market is flooded with operators who learned from the “school of hard knocks” and are prone to making the same machining mistakes repeatedly.

And to complicate matters, many machine shops lack a standard quality management system to inspect the parts being fabricated by their operators or technicians. You must steer clear of these types of vendors.

Top-tier CNC Machine Shops Perform Three Types of Inspection

Top-tier machining shops typically carry out three types of inspections at different stages of the manufacturing project;

- Inspection by the machine operator: here, the operator carries out various article inspections during (or immediately) after machining to identify tolerance problems. It involves using simple measuring tools such as go/no-go gauges and micrometers.

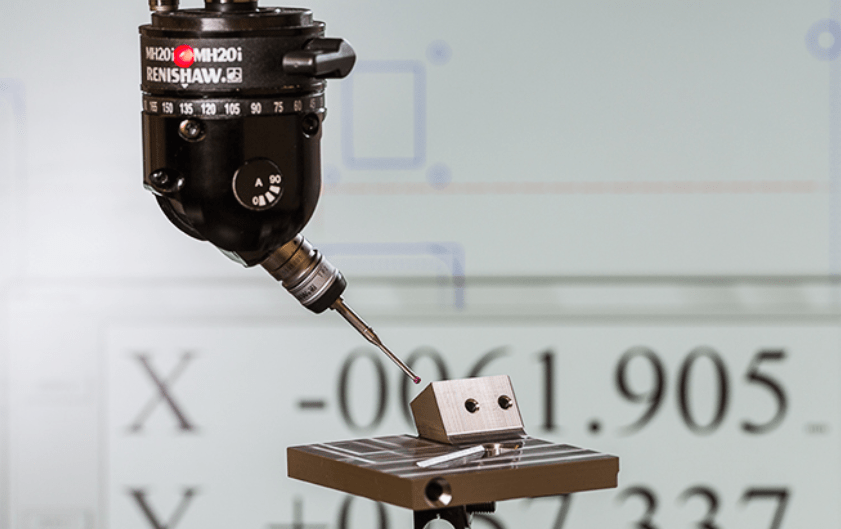

- Inspection via in-process probing: describes an automated way of verifying key features and tolerances of a part during the CNC machining process using programmed probes. These probes automatically monitor the process and adjust work coordinates and cutting tools accordingly.

- Inspection in the quality control (QC) department: it describes the inspection stage carried out on CNC machined parts by a team of quality control experts. These QC experts utilize height gages, microscopes, 2D projectors, micrometers, and coordinate measuring machines (CMM) to ensure that parts conform to the customers’ requirements. The picture above shows one of our QC team members at JC Rapid operating a CMM machine.

- JC Rapid is a leading provider of high-quality CNC machining services. We have a complete quality management system in place, and our facility is ISO 9001:2015 certified for quality.

What Separates JC Rapid’s Inspection Processes from the Rest?

Careful measurement, inspection and testing are necessary to ensure the conformance of your parts. We perform multiple inspections at every step of the product development journey, from incoming material verification to final 3D scanning. You will receive complete digital files and Certificates of Compliance so you can meet your own regulatory and performance goals.

Inspections and Review for Every Stage of Production

To ensure quality from start to finish, JC Rapid provides the following inspection and review services:

- Extensive incoming materials verification

- Design for manufacturing reviews for all quotes provided

- Contract reviews upon receipt of POs

- First article and in-process inspections

- Final inspections and testing with reports and certifications as required

About JC Rapid

Founded in 2002, JC Rapid is an innovator of on-demand digital manufacturing and continues to lead advances in rapid prototyping and CNC machining. We know what it takes to deliver a high-quality product on time and on budget. JC Rapid employs a team of experts in CNC machining, and takes the best approach to everything we do. Tens of thousands of product developers and engineers across the whole world trust JC Rapid to bring their products to life.

Questions? Contact our friendly sales team at engineers@jcrapid.com