Countless products today, from smartphones to supersonic jets, are made possible because of the reliability and versatility of CNC milling. It’s an ideal method for rapid prototyping, as well as volume manufacturing in plastic and metal. Let’s take a closer look at some of the remarkable advantages and applications for CNC milling.

What is CNC milling?

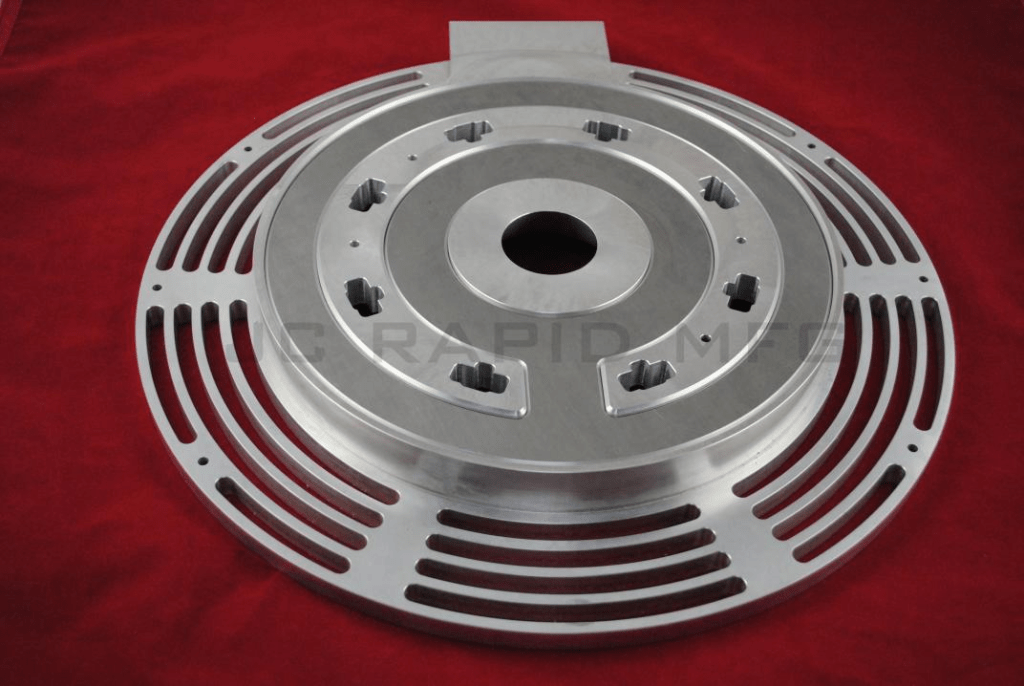

CNC milling is a manufacturing process that uses a cutting tool mounted on a rotating spindle to selectively remove material from a block of raw substrate. The workpiece is rigidly mounted to a table, and this table moves or rotates on different planes so the tool can work at many angles. Sophisticated CNC milling machines can have 5 or more axes of independent motion to make more complex shapes or to avoid having to move the workpiece to a separate machine.

How does CNC Milling work?

The CNC Milling process works by the machine reading coded instructions and then putting them into operation. It all starts with developing a 3D CAD file representing the final part. Once completed, the design is converted into a machine-readable format. CAM (Computer-Aided Manufacturing) software then exports this to a CNC machine program, usually in G-code format, which acts as the instructions, directing every move that the machine makes. This replicates the CAD design in the chosen material with high accuracy and efficiency.

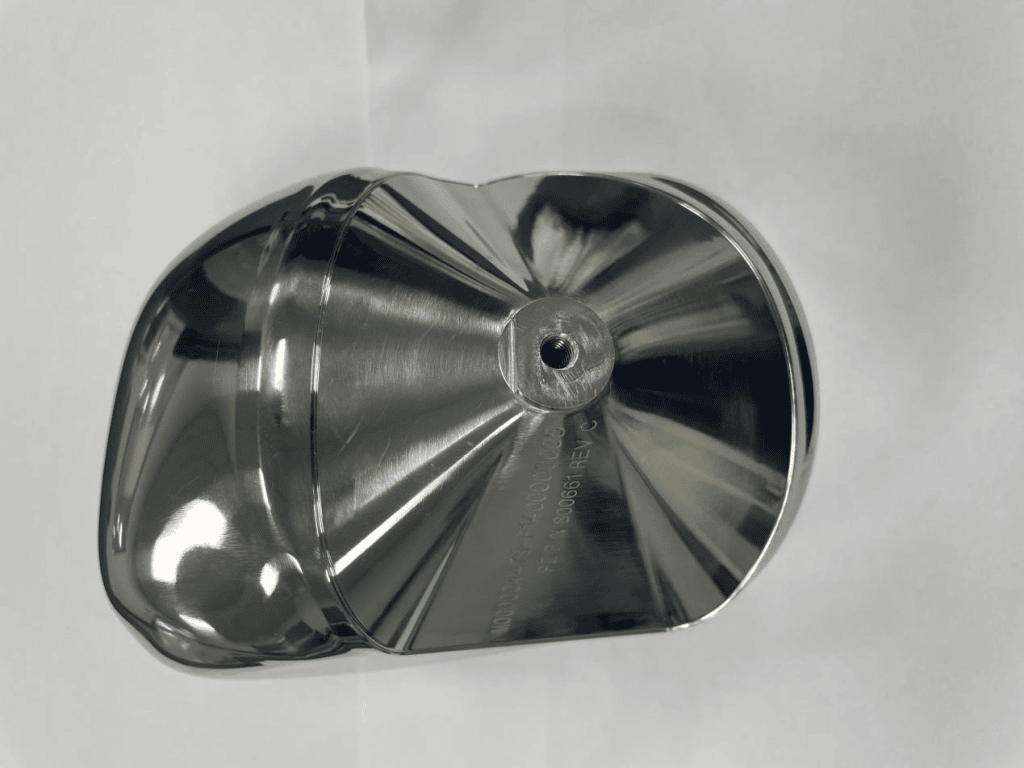

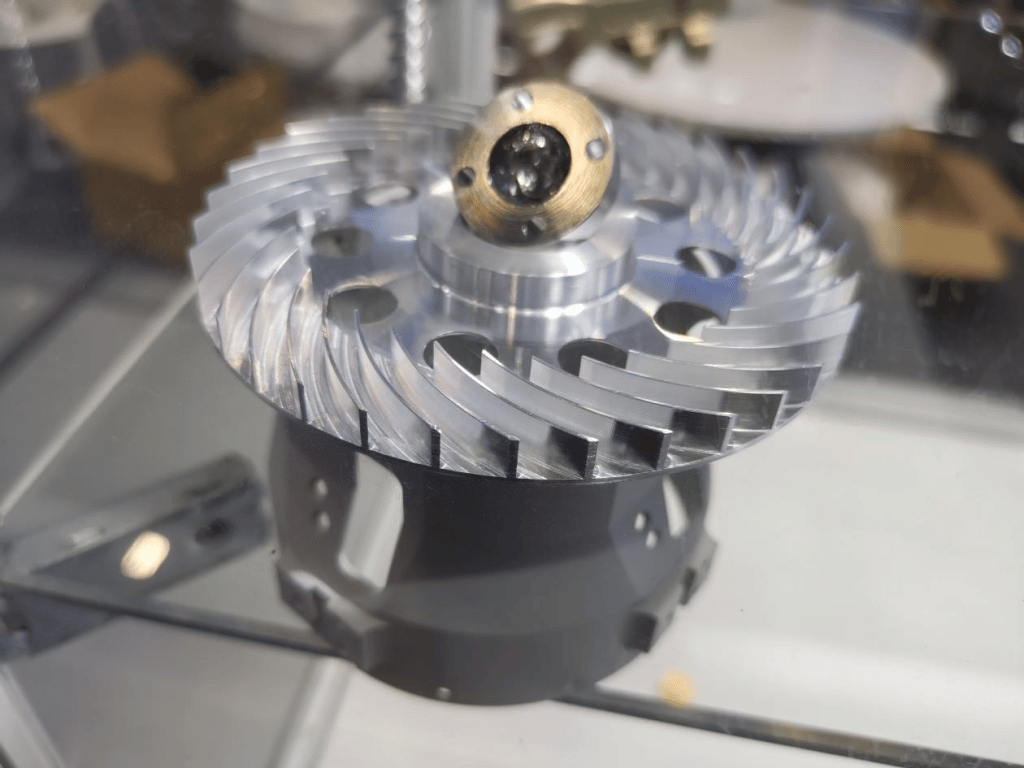

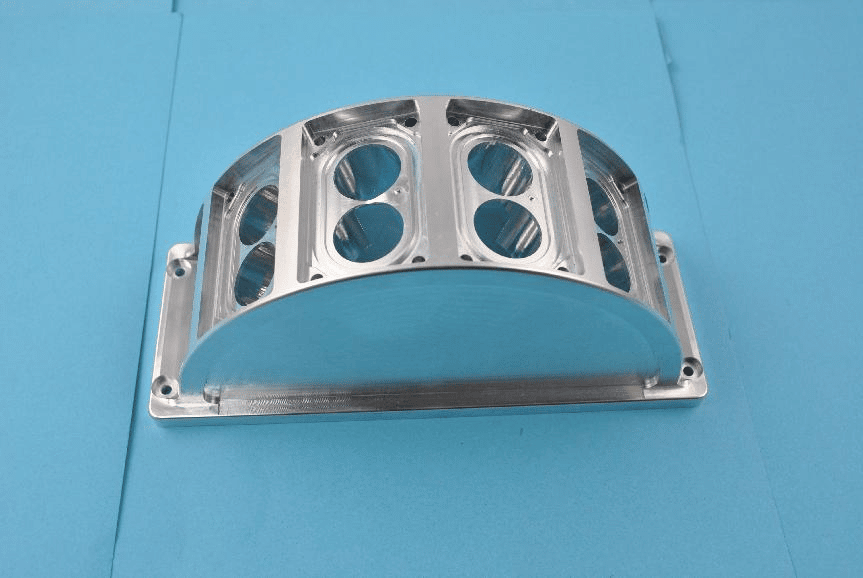

Using subtractive machining technology, CNC Milling can produce high and low volumes of highly complex and intricate parts. Material is removed from a blank workpiece, and the milling machine uses a rotating cylindrical tool called a milling cutter. Depending on the milling machine being used, the machine can cut in different angles and move along different axes.

The final part will have first been designed via CAD, or Computer-Aided Design, before being inputted into the milling machine for final production.

What does a CNC Milling Machine do?

A CNC milling machine makes intricate parts for several industries using subtractive machining technology. The milling machine cuts away at the workpiece and crafts the final piece via the 3, 4 or 5 axes. Depending on the number of axes the CNC milling machine has, the more complicated and intricate the final piece can be. A CNC milling machine is used by various industries – including aerospace and medical industries – to manufacture complex parts.

CNC Milling Process

Some milling machines will be more appropriate than others, depending on various factors. The complexity of the CNC milling process will be dependent on the design of the final part. The more structurally important and high-end the part or product is, the more complex the design may need to be.

For example, a more complex machine may need to be used for intricate designs requiring high precision, such as medical or aerospace components. This is to achieve the final design, finish, and aesthetic. Basic parts that are machined for more general use may not require such high precision or high-quality finish. Complex and intricate designs will typically require additional milling.

Often milling machines utilize either 3, 4 or 5 axes.

For simpler parts, fewer axes are needed to achieve the final design. Simple geometries can generally utilise a 3-axis milling machine. They are easy to program and operate, achieving excellent accuracy at a low cost. The cutting tools are attached to a spindle that works on three linear axes. They can spin at thousands of RPM, meaning even the sturdiest of materials can be cut through with ease and accuracy.

3-axis machines are the most common variety of milling machines and can cut vertically (Z-axis) and in an X and Y direction. However, it’s usually not possible to machine undercuts with a 3-axis milling machine. These are features that cannot be accessed with a standard end mill. This means that more complex designs may require a more complex milling machine.

The 4-axis milling machine is more sophisticated, with the additional ability to rotate on the X-axis (similar to a lathe).

5-axis milling machines include rotation in both the X and Y-axis. They are the most complete milling machines available and are implemented for highly complex designs such as medical devices and implants for the medical industry, impellers and aerospace structures.

Top Tip: Read our guide understanding the CNC Milling process

Top Tip: Read our guide How to Machine Square Corners with CNC Milling

Types of CNC Milling

Vertical milling

With vertical milling, a 3-axis milling table is the work surface, which sits below the arm, to which a spindle is attached.

The spindle can be stationary if a vertical turret mill is used. In this case, the table moved along both X and Y axes. Meanwhile, the table only moves along the X-axis if a bed vertical mill is used. The spindle travels along the length of the arm in the Y-Axis direction.

Horizontal milling

With horizontal milling, the spindle operates horizontally instead of vertically, and all other components are similar to vertical milling. Generally speaking, horizontal mills are best suited to heavier projects or longer projects. They are also suited to parts that require a large amount of material to be removed as the swarf falls away from the part and cutter.

Face milling

The cutting tool’s axis of rotation is perpendicular to the surface of the workpiece.

It employs face milling cutters, with teeth both on the periphery and the tool face, the latter of which is used for finishing applications. Face milling is also used to create flat surfaces and control a finished piece. Face milling can produce higher quality finishes than other milling processes and is compatible with vertical and horizontal milling machines.

Plain milling

The cutting tool’s axis of rotation is parallel to the surface of the workpiece. Plain milling cutters have teeth on the periphery that perform the cutting operation. Both narrow and wide cutters are used. This allows for deeper cuts and for larger surface areas to be worked on. A course and fine-toothed cutter are both used. Slow cutting speeds and fast feed rates are used for the course cutter and vice versa for the fine-toothed cutter. This enables a more detailed final part.

Angular milling

This is a milling operation where the cutting tools’ axis of rotation is at an angle relative to the surface of the workpiece. Therefore, single angled milling cutters can produce more angular features, such as grooves, serrations, or chamfers.

Form milling

Form milling is best used for milling operations where more irregular surfaces are involved. Contours, outlines, edges, or parts with curved, flat surfaces. It employed milling cutters or fly cutters specialised for particular applications – for example, concave cutters or corner rounding cutters. Hemispherical or semi-circular designs or other similarly intricate designs with complex parts would benefit from the form milling technique.

Types of a Milling Machine

As there are various types of CNC milling, there are also a number of unique milling machines with distinct characteristics and functions. Some different types of milling machines are:

Ram-type: This machine allows the machine tool to manoeuvre on the XY axes through a spindle that is fixed to a movable arm on the column. Horizontal milling machines are often ram-type.

Knee-type: Knee-type machines will vertically adjust the worktable instead of the spindle. The knee will lower and raise the worktable along the column to reach the machine tool. Plain milling is often done on a knee-type machine.

Planner-type: The worktable is fixed along the YZ axes in this milling machine with spindles that are able to move along the XYZ axes. They can also simultaneously support up to four machine tools.

Bed-type: These milling machines have the workpiece fixed below the cutting tool. The machine tool may be able to move along the XYZ axes.

Benefits of CNC Milling process

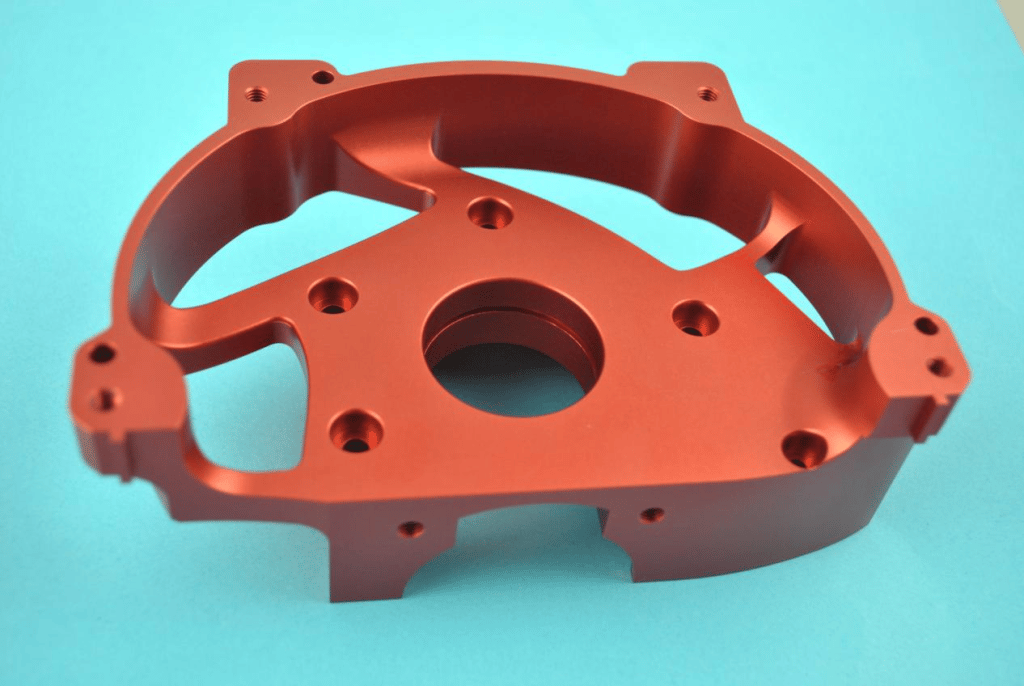

Advanced CNC milling machines are equipped with features such as integrated touch screen software control, chip management, and swing arm Automatic Tool Change (ATC). Here are 5 major benefits of these automated milling machines for CNC milling plastic and metal:

Safety: Machine operators do not need to crouch or bend while using a CNC machine. Thus, milling processes become easier and safer when using CNC machines. The components to be machined are placed in an enclosed area, which reduce chances of accidents.

Extreme Accuracy Guaranteed: The accuracy of CNC milling remains unmatched and superior to traditional milling machines. CNC machines are equipped with advanced features, and software, which ensures the accuracy of the milled part. Also, the CNC milling process ensures high positional accuracy, as well as a high degree of repeatability. Updated software and individual parts are two requisites, which help ensure production efficiency, and part accuracy. Most software programs are easy to understand, and novice operators can follow manufacturer’s instructions when using for the first time. The CNC machines allow greater precision, which is typically 0.0001 inch.

Improves Efficiency: The CNC milling machine is designed for a non-stop performance, which allows manufacturers use them continually. The machine only needs to be switched off occasionally for maintenance and repair. Also, the machine requires no warm-up time, which mean they can be operated anytime. Most software controlled precision milling machines allow idea simulation, which means there is no need to build or use a prototype. Once the software is programmed into the machine, it can produce countless replicas with the same precision every time. The CNC machines provide greater throughput because they are five times faster than traditional machines.

Versatility: Manufacturers have to deal with multiple materials on a daily basis. They may be required to work with a wide variety of plastics or metals. CNC milling machines allow these manufacturers to shape and trim materials with losing on efficiency or quality. Since these machines allow working with multiple materials, machine operators can multi-task and create different parts at a time.

Low Overhead Costs: Like most other automated CNC machines, the CNC milling machines require less supervision. A manufacturer can employ a single person to oversee the operation of various CNC machines.

About JC Rapid

Founded in 2002, JC Rapid is an innovator of on-demand digital manufacturing and continues to lead advances in rapid prototyping and CNC machining. We know what it takes to deliver a high-quality product on time and on budget. JC Rapid employs a team of experts in CNC machining, and takes the best approach to everything we do. Tens of thousands of product developers and engineers across the whole world trust JC Rapid to bring their products to life.

Questions? Contact our friendly sales team at engineers@jcrapid.com