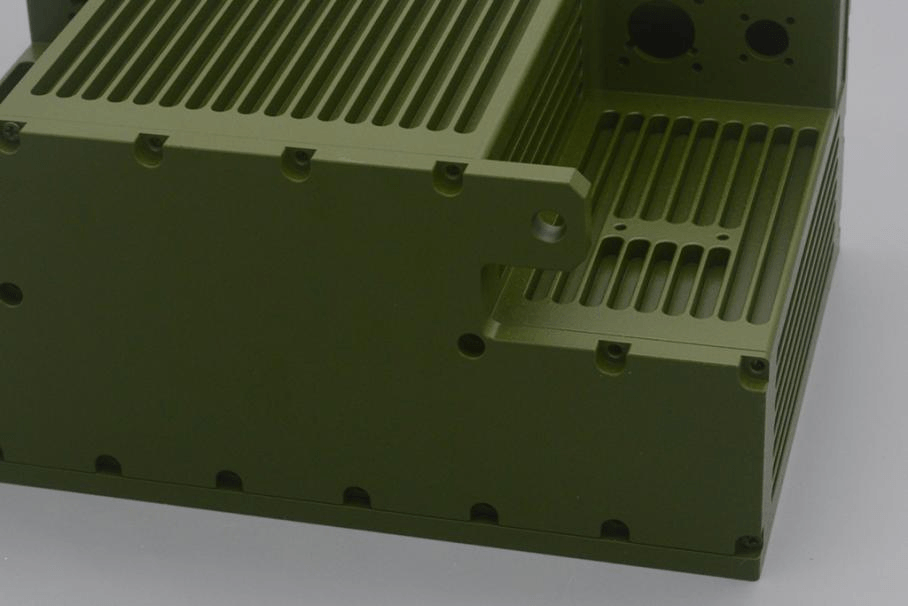

Military UAV Accessories and Military reinforced chassis

Project:Military UAV Accessories and Military reinforced chassis

Services: CNC milling, Sanding, Bead Blasting, Color Anodizing,

Material: AL-7075 aluminum

Lead Time: 10days

Quantity: 200units

About project

The structure of military UAV meets GB/T 19520.12-2009 standard and relevant military standards, and ADAPTS to the environmental requirements of airborne, ship-borne, vehicular and ground station room.

We have been engaged in metal processing for more than ten years. We are experienced in this field and can deal with all kinds of problems encountered in the process, including CNC processing, die casting processing, vacuum welding technology, CAE analysis and so on

The chassis can use VPX, CPCI, PCIe, PMC, PXI/PXIE, VME and other bus structures, high mechanical structure strength, strong vibration impact resistance, excellent heat dissipation performance, can use liquid cooling heat dissipation

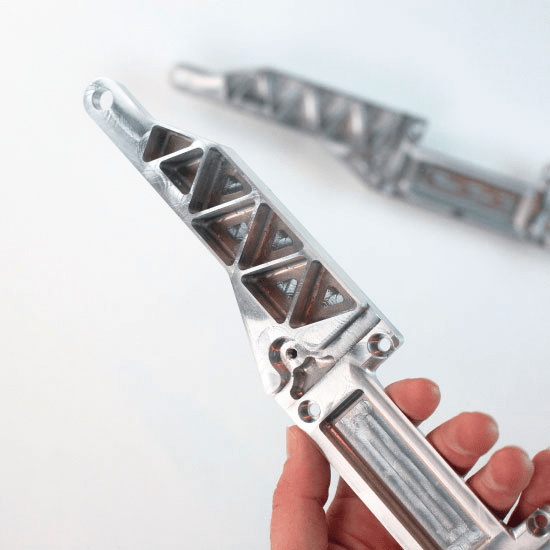

How The Parts Were Made

The Milled Case

7075 aluminium alloy (AA7075) is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It is one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts

Uploading CAD File

When the material is ready, the 3D CAD drawing file is imported into the software. Programmers use this software to generate 3D tool paths using CAD design files. Then, we take these tool paths as a set of instructions output, tell the machine every necessary movement to make the finished part, and select the most appropriate cutting tool to ensure that it produces the best quality, speed and precision, the whole process is accurately calculated, and the product will be automatically mass-produced.

Anodizing

A variety of surface textures and finishes are applied to this part. The next step was anodization. Anodizing is an ideal method to improve corrosion resistance, durability and beauty of aluminum parts. Hardcoat Anodize is Type III which is done under more exacting process conditions resulting in a harder, denser, thicker, and more abrasion resistant coating. Hardcoat thicknesses can vary from 0.0005 to 0.0030” and beyond but is dependent on the specific alloy being anodized.

If you enjoyed reading this article, are you ready to move on to your next project? Send your CAD drawing file and our engineers will provide you with a free quote and project review. Send email:mold@rjcmold.com

Request A Free CNC Machining Quote Now

We reduced CNC machining quote time by 90%. Most quotes are delivered within 24 hours, depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you have received the quote and to answer any questions you may have about your options.