E-Cigarette Prototypes

Project:E-Cigarette Prototypes

Services: CNC milling, Sanding, Bead Blasting, Color Anodizing, Laser Etching

Material: AL-6082 aluminum

Lead Time: 35 days

Quantity: 1000units

About The Product

e-cigarette is an elegant and unique smokeless device for both men and women. also a proprietary smoking blend that comes in several flavors, is nicotine-free, satisfying and available nowhere else.

About The Project

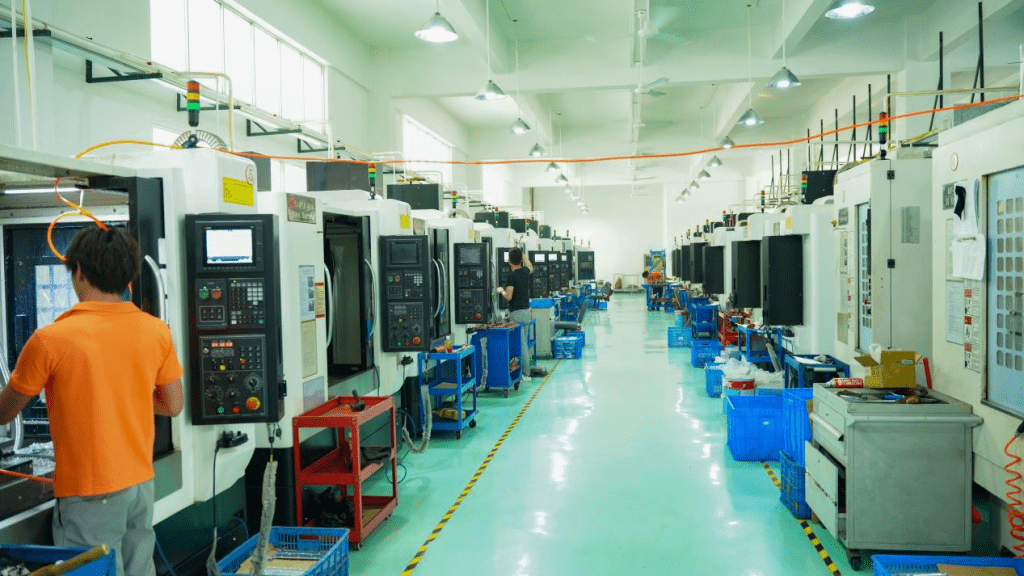

Recently made a CNC milling aluminum case for a new type of electronic cigarette. They have different anodized colors for each size to test the market. To achieve this, we did some mini-batch runs

How The Parts Were Made

The Milled Case

we use the aluminum material AL-6082. This is a relatively new aluminum alloy that’s superior to 6061 for strength and corrosion resistance. It machines very well and produces an excellent surface finish when the right cutting tools are used.

Uploading CAD File

When the material is ready, the 3D CAD drawing file is imported into the software. Programmers use this software to generate 3D tool paths using CAD design files. Then, we take these tool paths as a set of instructions output, tell the machine every necessary movement to make the finished part, and select the most appropriate cutting tool to ensure that it produces the best quality, speed and precision, the whole process is accurately calculated, and the product will be automatically mass-produced.

Bead Blasting The Surface

After precise CNC milling, the aluminum portion of the surface is sandblasted to create a uniform matte finish.

Fixtures To Hold The Part

Many professional projects require such fixtures to support the product. In this case, they help the operator to hold and rotate the parts safely, ensuring the perfect surface of the product and requiring professional personnel to operate it

Anodizing

A variety of surface textures and finishes are applied to this part. The next step was anodization. Anodizing is an ideal method to improve corrosion resistance, durability and beauty of aluminum parts. We made additional fixtures to attach multiple pieces to a tree, while making sure the pieces didn’t touch each other. Ensure that the oxidized surface of the product is the same, so that you can get a perfect surface of the product

Laser Marking

After anodization, a laser laser is followed to precisely evaporate the anodized surface, changing the surface chemistry at the molecular level to make a permanent perfect marker

Inspection

At RJC, we also use our own internal metrological tests to examine all materials. Process control and quality inspection report, which must be checked before shipment, to ensure that 100% of the products pass the quality inspection, we will ship to customers.

The Finished Product

The final form of the product is just like the products in the market. The delicate surface treatment is exactly the strength of our company

If you enjoyed reading this article, are you ready to move on to your next project? Send your CAD drawing file and our engineers will provide you with a free quote and project review.Send email:mold@rjcmold.com

Request A Free CNC Machining Quote Now

We reduced CNC machining quote time by 90%. Most quotes are delivered within 24 hours, depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you have received the quote and to answer any questions you may have about your options.