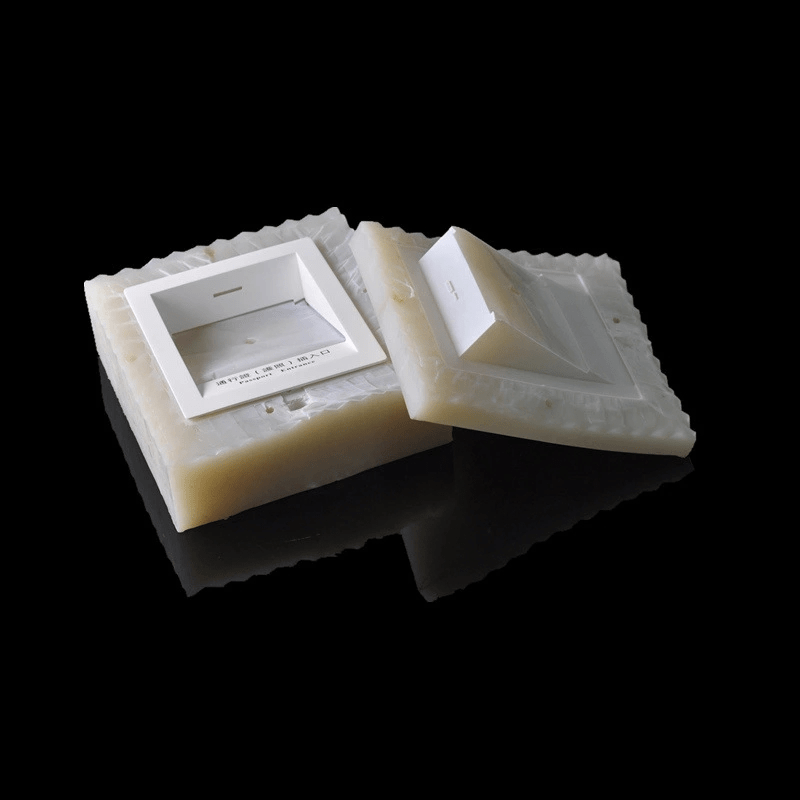

Home leak cap

Project:Home leak cap

Services: vacuum casting,

Material: silicone mold ,abs

Lead Time: 2days

Quantity: 100units

How The Parts Were Made

Prototype production

Before we can make the CNC silicone handplate model, we need to make a prototype. The prototype can be 3D printed or CNC made.

Silicone mold

Once the prototype is ready, start making silicone molds.

After eight hours of drying, the silicone mold was cut open and the prototype was removed. Now the silicone mold is ready.

Pouring

The liquid gum material is injected into the silicone mold and dried. The service life of transparent silicone mold is about 20 molds. Suitable for full small batch customization

Use CNC, SLA, or 3D printing to make a prototype for the nozzle

Board around the prototype in preparation for making the mold

Pour the vacuum liquid silica gel into the mold with the vacuum machine to cover all the products

Put the mold into the oven to bake in order to accelerate the solidification of the silicone mold

Take the prototype out of the mold

According to the material needed by the product, the vacuum is pumped and the material is poured, and the finished product is reproduced

Request A Free CNC Machining Quote Now

We reduced CNC machining quote time by 90%. Most quotes are delivered within 24 hours, depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you have received the quote and to answer any questions you may have about your options.