Acceleration sensors

Use: It is designed to detect and monitor vibrations and shocks in wind field environments. The main controller provides accurate acceleration information to avoid any excessive vibration as soon as possible.

Services: CNC milling, sandblasting, anodizing, laser marking

Material: Aluminum 6061-T6

The Project

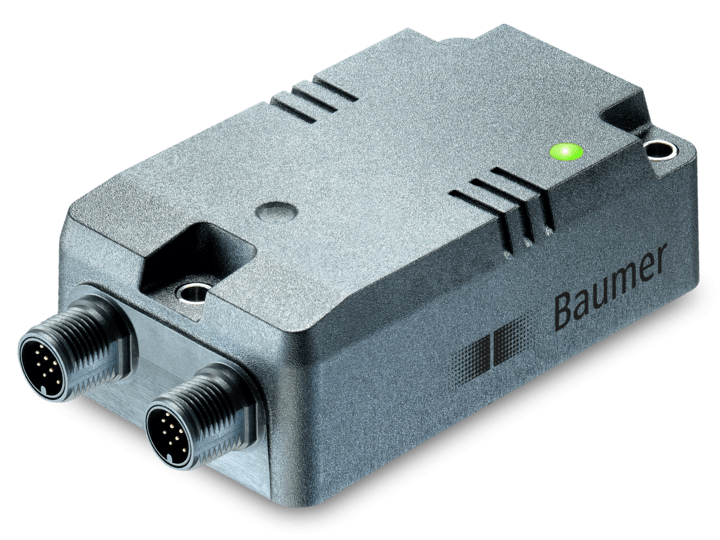

Our team at RJC was approached to help build an enclosure for their sensor . The enclosure is made of three parts, milled from aluminum 6061 with a T6 temper. Some of the parts were color anodized, while others were given a clear alodine coating.

The Product

The customer is a company that specializes in manufacturing sensors and is passionate about sensor technology, encoders, measuring meters and automated image processing components. This product is suitable for wind energy monitoring and is essential to the precision of data

Material Inspection

As we do with all of our projects, we double-checked that the incoming raw material marked as “AL 6061-T6” was exactly that.

CNC Milling

Once the raw material was prepared, we built separate holding fixtures for each of the three components.

The cover for the enclosure needed to be milled on both sides. The most efficient way to do this was by putting two fixtures into one machine. After completing one side the part was removed, flipped over, placed on the adjacent fixture and completed.

Sandblasting

Freshly milled aluminum has a polished look that is almost as shiny as chrome. Unless treated, this surface will quickly oxidize when exposed to the atmosphere.

After sandblasting, the parts achieve a uniform matte finish. The middle section and the enclosure cover were then given a clear alodine coating. An alodine finish is a chemical treatment used on aluminum, magnesium and other metals to provide corrosion protection and to act as a base for other surface treatments like painting or powder coating. Alodine finishes are usually transparent.

Laser Marking

After sandblasting, both the top and bottom sections were laser marked.

Request A Free CNC Machining Quote Now

We reduced CNC machining quote time by 90%. Most quotes are delivered within 24 hours, depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you have received the quote and to answer any questions you may have about your options.