CNC Turning Services

JCRAPID can use the CNC turning process to make parts or product prototypes and mass-produce them. General threading, and CNC machining of round parts including shafts, worms, and balls.

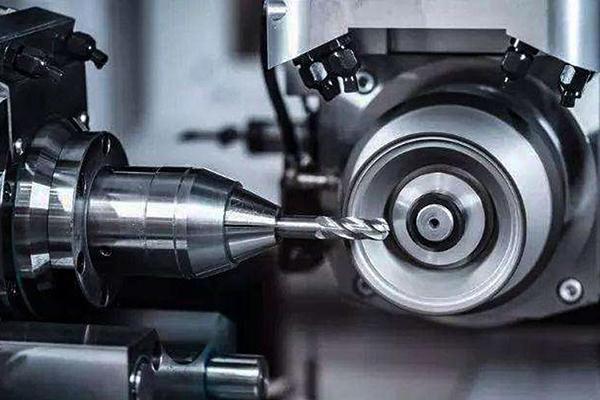

Robust CNC Turning Service

Our expert CNC machinists and tool and die makers use state-of-the-art equipment to meet or exceed our clients’ high quality standards including the most complex parts. As a result, we can produce close tolerance parts (+/- .001” or better) on parts as large as 10″ diameter. We continue to reinvest in the latest equipment. In turn, our clients receive the lowest cost per part, highest quality and best delivery possible. Our CNC turning center has a full C-axis, Y-axis, and an automated tool presetter. The tool presetter allows for automated tool wear detection while virtually eliminating downtime therefore maximizing production efficiency and reducing the cost per part.

CNC Horizontal Turning

JCRAPID offers CNC horizontal turning with the capability to produce parts weighing up to 950 lbs., up to 44″ in length and 25″ in diameter. We can also produce parts as small as 1/8″ wide, working to tolerances. With a 3-axis, live tooling-equipped turning center, our capabilities include internal and external threading, knurling, profiling and much more.

CNC Vertical Turning

JCRAPID offers CNC vertical turning services for products in a wide range of industries—from construction and farm equipment to aerospace and defense. We produce precision machine components to tight tolerances with short lead times. Parts can be manufactured up to 21.5″ long, with a maximum diameter of 51″ and a maximum weight of 20,000 lbs. Our capabilities include contour and straight turning, internal forming, counterboring, pocketing and much more.

CNC Turning Tolerances

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Size Limitation for CNC Turning

| Limitation | Parameter (Metric) |

| Max swing diameter | 0.3~3600 mm(0.011~141.732″) |

| Max cutting length | 0.5~1500 mm(0.019~59.055″) |

JCRAPID is able to produce different sizes of products. While there are still limitations existing in CNC machining. Factors like size could cause some limitations, so we detailed a size limitation table of CNC machining above for you to refer to. It is vital thing for both designers and engineers to be familiar with this limitation before designing.

Precision CNC Turning Service Provider

At The JCRAPID, we provide precision custom machining at competitive prices to various organizations and industries.

With more than several decades of experience, we’ve refined our processes, leading to quick turnarounds, on-time deliveries, fast communications, and minimal waste. Additionally, we adhere to our strict standards for quality, demonstrated by our ISO 9001:2015 accreditation and compliance with U.S. MIL-I-45208A standards.

Build your partnership with China premier machine shop by contacting us today to discuss your CNC turning needs.

Our CNC Turning Capabilities

JCRAPID has many choices for CNC turning service, we can not only provide you the fine quality of our products but also the best service, our sophisticated engineer team will offer you a perfect turning plan, for the quality of products, we also ensure you with our ISO9001:2008 and TS16949 quality system certificates. We will try our best to make the production within 1day, then the products will be sent to your door as fast as we can.

Fast Tooling – We offer CNC Services for rapid tooling, delivering our product in a short time.

Rapid Prototyping – Rapid Prototyping for a large scale of materials, several different types of molds available.

Mass Production – Products manufacturing available and quality guaranteed.

Available Materials for CNC Turning

| Aluminum Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc. | Steel Mild Steel, Alloy Steel, etc. | Plastic PET / PVC / ABS / PC / PE / PTFE / POM / PMMA / Nylon / PP / Peek, etc. |

| Cooper C11000 / C12000 / C12000 / C36000, etc. | Stainless Steel Stainless-steel 303 / 304L / 316L / 416 / 440C | Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc. |

Surface Finishes for CNC Machining

With a wide selection of surface finishes, JCRAPID can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

| Service | Surface finishing options at SuNPe | |||

| CNC Machining | ◆Primer | ◆Powder Coating | ◆E-coating | ◆Brushing |

| ◆Painting | ◆Polishing | ◆Plating | ◆Passivation | |

| ➢2K | ➢Tumbling | ➢Chrome | ◆Sandblasting | |

| ➢Opaque | ➢Mechanical | ➢Zinc | ◆Logo Printing | |

| ➢Transparent Color | ➢Fumigation | ➢Nickel | ◆Heat treatment | |

| ➢UV-resistant | ➢Chemical | ➢Copper | ◆Anodizing(Aluminum) | |

| ➢EMI shielding | ➢Electrolytic | |||

| ➢Liquid rubber | ||||

What is CNC turning?

CNC turning involves applying a cutting lathe to a rotating blank workpiece to form the desired part. The workpiece rotates on a vertical or horizontal axis during production while the automatic lathe moves around it. As part of high-volume production, CNC turning is accurate, repeatable, and scalable, ideal for creating parts with simple geometries and round or cylindrical shapes.

Please send us your CAD files to start your CNC turning project. We’ll work with you to optimize your design and select your materials, then bring your project to production quickly and efficiently.

For more on-demand manufacturing options, browse our CNC machining capabilities, including our CNC milling services.

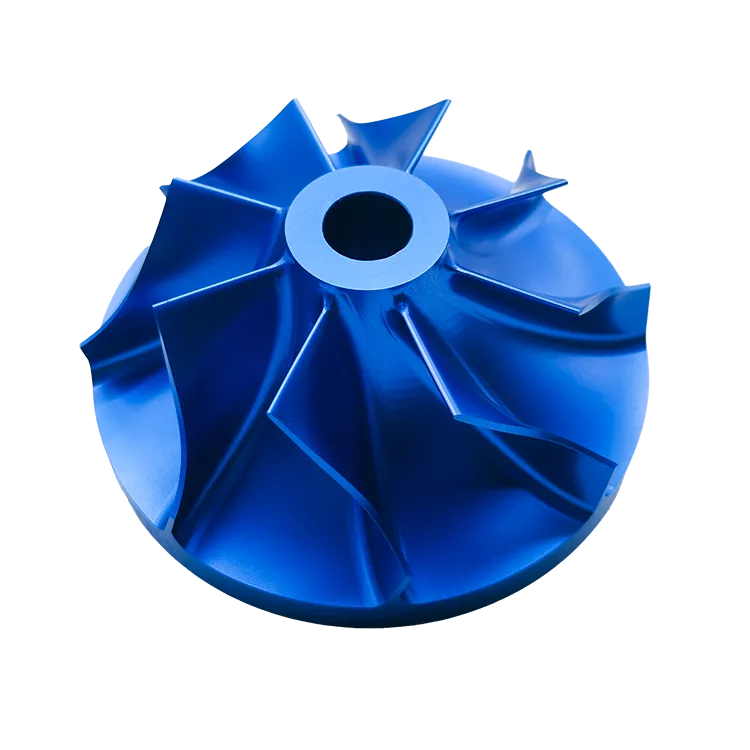

Gallery of CNC Turning Parts

The gallery showcases precision turned prototypes and parts from our valued customers.

Why Choose JCRAPID for CNC Turning?

Rapid Turnaround – We use the latest CNC turning machines and cutting tools to produce high-precision, fast-turned parts within one day.

Wide Range of Materials – Choose from more than 100 kinds of metal and plastic materials, and provide corresponding quality assurance.

High Precision – Provide unparalleled precision and quality without cutting corners. High precision tolerances range from +/- 0.0025mm(0.000098”), according to customer specifications.

Competitive Price – We have a stable supplier of raw materials and can quickly provide customers with competitive quotations.

Engineering Support – Whether the customer needs to machine 1 or 10,000 parts, we have a professional engineers team to provide technical support.

Our CNC Turning for Various Industrial Applications

JCRAPID’s cost-effective and reliable CNC-turned parts see great use as crucial pieces in equipment for medical, consumer goods, and automotive fields, and more.

Are You Ready To Start Your Next CNC Project?

With a range of finishing services and guaranteed quality, thanks to our inspection services, you can trust you will receive great parts every time. Once you send us your 3D CAD file for a free quote, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements.